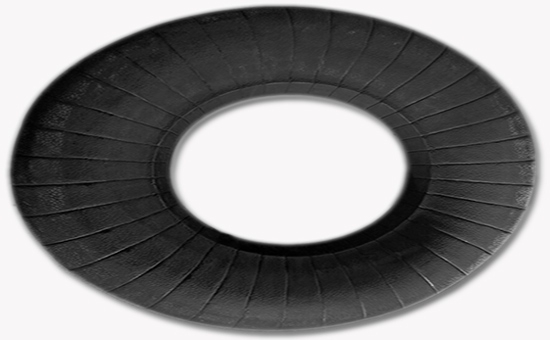

The water tire is a rubber bladder used in the vulcanization process of the outer tire that can conduct the heat medium, which can promote uniform tire vulcanization. Initially, the inner rubber of the water tyre was processed with natural rubber as the raw material, but the water tyre products have poor air permeability, heat resistance and aging resistance. When butyl rubber is used in the inner rubber of natural rubber water tyres to improve the comprehensive performance of water tyres, there are some technical problems that are difficult to solve, so more people have turned their attention to butyl reclaimed rubber.

1. The recommended amount of butyl reclaimed rubber in the inner rubber of the water tire

The butyl reclaimed rubber processed from waste butyl inner tubes retains the basic performance characteristics of butyl virgin rubber. The reclaimed rubber product with high butyl content has high strength, good elasticity, high fineness and strong air tightness; it has mechanical strength compared with butyl virgin rubber. 2YLYY326 is slightly worse but has better plasticity, fluidity, faster vulcanization speed, and better compatibility with natural rubber. Therefore, it can be used with natural rubber to prepare water tire inner layer rubber to improve water tire air tightness and aging resistance while reducing Raw material costs.

In actual production, the 300% tensile stress and tensile strength of the inner rubber of the water tire decrease with the increase in the amount of butyl reclaimed rubber, and the permanent deformation at break increases slightly. After aging, the 300% tensile stress and tensile strength of the rubber compound The tensile strength is significantly improved. In general, the addition amount of butyl reclaimed rubber in the inner rubber of natural rubber tires can be controlled between 10-20 parts, and the product comprehensive index is better.

2. Formula design of water tire inner layer rubber containing butyl reclaimed rubber

When natural rubber and a small amount of butyl reclaimed rubber are used together to produce water tire inner rubber, the accelerator NOBS is usually used in combination with a vulcanizing agent. NOBS is a late-acting high-speed vulcanization accelerator with excellent after-effect, easy to disperse during vulcanization, and no vulcanized rubber. Spray frost, not easy to change color, add 0.1-0.2 parts of anti-scorching agent if necessary. The combined use of carbon black N660 and heat-resistant reinforcing agent can significantly improve the tensile stress, resilience, flex resistance and heat resistance of the vulcanizate. The combination of protective wax and antioxidant RD, 4020 can significantly improve the aging resistance of the inner layer glue.

3. Mixing skills of water tire inner layer rubber containing butyl reclaimed rubber

When natural rubber and a small amount of butyl reclaimed rubber are used to prepare the inner rubber of the water tire, a two-stage mixing process is generally selected. One stage of mixing is carried out in an internal mixer: raw rubber, butyl reclaimed rubber, zinc oxide and stearic acid, etc.→pressing mound→carbon black and aromatic oil→pressing mound→lifting mound→discharging rubber. Two-stage mixing can be carried out in an open mill, and the order of feeding: one-stage rubber compound→sulfur and accelerator; or in an internal mixer: one-stage rubber compound→sulfur and accelerator→pressing mound→lifting mound →Pressing mound→lifting mound→pressing mound→lifting mound→discharging glue.

In actual production, the debinding temperature can be controlled between 150-160℃. Reasonable use of butyl reclaimed rubber in the inner rubber of the water tire can not only improve the aging resistance of the water tire, extend the service life of the water tire, but also reduce the cost of raw materials and reduce energy consumption. The editor will continue to discuss with you about butyl regeneration. The application of glue in water tyres.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits