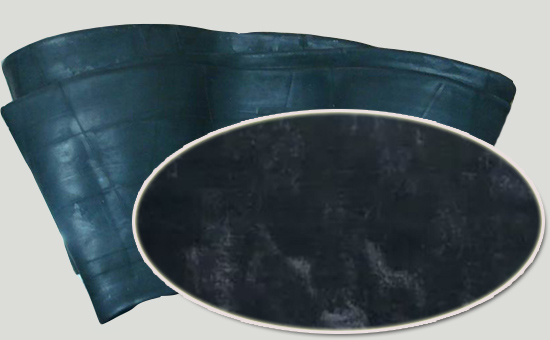

Butyl regenerated rubber has good airtightness and is often used for the production of high-airtight rubber products such as inner tubes and water tires. However, when using butyl reclaimed rubber (including all reclaimed rubber) to produce rubber products, a problem of blooming may occur when an improper operation is performed, which makes rubber product manufacturers feel headaches. So what are the reasons that lead to butyl regenerated rubber spray? What solution is there?

The use of butyl reclaimed rubber to produce rubber products has a phenomenon of blooming, which is mainly compounded with sulfur, waxes, accelerators, antioxidants, plasticizers, and fillers in butyl rubber products. It migrates from the interior of rubber compounds or products. The phenomenon of the appearance of frost and other substances on the surface is due to the fact that the amount of these complexing agents exceeds the solubility in the rubber or vulcanizate and changes from the metastable state to the steady state. Say goodbye to the blooming of reclaimed rubber products, you can take the following measures:

1. High-temperature baking, according to the characteristics of the compounding agent used in the butyl reclaimed rubber compound and the rubber product, the suitable high-temperature curing temperature and time are selected.

2. The variety of compounding agents should be selected correctly and the dosage is not too high. For example, if the amount of sulphur is not used in an excessive amount, the butyl regenerated rubber product can be sprayed. It is better to use insoluble sulphur for products that cause sulfur blooming, and try to Reduce the amount of sulfur.

3. Addition of proper amount of pine tar oil and liquid softening agent, such as Gumulon, to the butyl reclaimed rubber product formula can increase the solubility of the rubber material, promote the even dispersion of the powdery compounding agent in the rubber compound, and reduce the occurrence of saturated frosting phenomenon. .

4. Combination of antioxidants. Anti-aging agents can relieve the aging time of butyl reclaimed rubber products, but excessive use of the same anti-aging agent will exceed the solubility of the anti-aging agent in the rubber compound, which will cause the surface of butyl regenerated rubber products to bloom. This time It is necessary to use a variety of anti-aging methods to effectively prevent the occurrence of blooming. In order to ensure uniform dispersion of the ingredients in this process of mixing, rubber homogenizers and dispersants can also be added.

5. The use of chemical cleaning agent wipes, the principle is to use chemical reactions to complete the rubbing of rubber products to solve the problem of surface blooming.

6, roughing the surface, the surface of the surface of the cream is polished off so that the rubber surface is not smooth.

7. The solubility of the compounding agent used in the summer butyl reclaimed rubber product in the rubber compound is not the same as the solubility of the rubber compound in winter. Therefore, the amount of the molecular compounding agent should be reduced in the formulation of the recycled rubber product in winter to avoid the frosting of the butyl reclaimed rubber product.

Do you have a better solution for the blooming of reclaimed rubber products?

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits