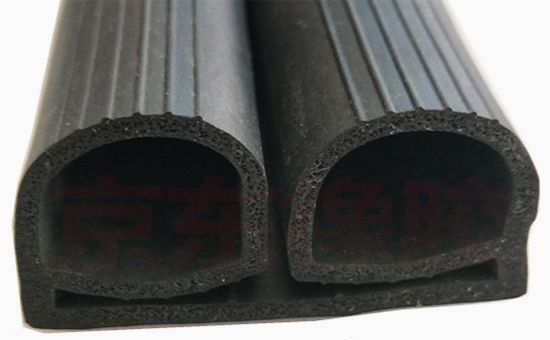

The rubber sealing strips produced by EPDM rubber and EPDM reclaimed rubber can maintain good sealing effect indoors and outdoors for a long time, which is inseparable from the excellent high temperature resistance and anti-aging performance of EPDM rubber; In addition to the type of rubber, the mechanical properties of the elemental static sealing strip are one of them. Improving the mechanical properties of the EPDM static sealing strip can improve the sealing effect of the sealing strip and prolong the service life of the sealing strip.

1. Appropriate increase of EPDM raw rubber dosage

EPDM reclaimed rubber is an ideal raw material for the production of rubber products and lowering the cost of raw materials instead of EPDM. Many EPDM seal manufacturers will follow this method naturally; EPDM reclaimed rubber is EPDM. The products processed from waste EPDM rubber products have been seriously damaged and the mechanical properties have been degraded. Therefore, when EPDM reclaimed rubber/rubber is used to produce static sealing strips, the amount of EPDM raw rubber can be appropriately increased. Improve the mechanical properties of static seals.

2. Adjust EPDM static sealing strip vulcanization system

It is well known that the vulcanization properties of vulcanizates are closely related to the degree of vulcanization of the rubber compound, the type of crosslinks and the distribution of crosslinks. Therefore, when using EPDM reclaimed rubber or EPDM rubber to produce static seals, it is possible to adjust the vulcanization in the formulation. The system aims to improve the mechanical properties of static seals.

Under normal circumstances, the tensile strength and tear strength of EPDM vulcanizate increase with the increase of the density of the crosslinked network, and then decrease after reaching a certain peak. The higher the density of the crosslinked network, the extension of the vulcanizate The greater the stress and hardness, the lower the elongation at break. When the degree of vulcanization is low, the increase of the crosslink density of the EPDM vulcanizate can increase the tensile strength of the rubber compound; however, when the vulcanization degree of the rubber compound is sufficiently high, the molecular chain orientation and crystallization are difficult, and the tensile strength of the rubber compound is lowered.

The mechanical properties of EPDM vulcanizate have a great relationship with the type of vulcanization crosslinks. Under normal circumstances, the elongation stress of EPDM vulcanizates with carbon-carbon crosslinks will increase rapidly with the increase of vulcanization degree. The EPDM vulcanizate, which is mainly composed of polysulfide bonds, has a particularly slow increase in the tensile stress when the degree of vulcanization is continuously increased. The tensile strength of the EPDM vulcanizate decreases in the order of increasing the number of ionic bonds → polysulfide bonds → disulfide bonds → monosulfide bonds → carbon-carbon bonds.

When using EPDM/recycled rubber to produce static sealing strips, the static sealing strips of different working places require different mechanical properties such as tensile strength, tensile stress, hardness and elongation at break, and need to be formed according to vulcanized rubber. The type and quantity of cross-linking bonds are selected according to the appropriate type of vulcanizing agent, and the accelerator is used together. The mechanical properties of the EPDM compound after vulcanization in the traditional sulfur vulcanization system are better.

When using EPDM/recycled rubber to produce static sealing strips, the type and amount of reinforcing agent and filler in the reinforcing filling system, the type and amount of softening oil in the softening system will also affect the mechanical properties of the EPDM sealing strip. If you are interested, we will be tomorrow.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits