EPDM rubber has excellent resistance to high and low temperature and aging resistance. It can be used to produce cold-resistant hoses and can maintain good performance under specified low temperature conditions for a long time. EPDM reclaimed rubber is ideal for EPDM rubber. Alternative materials, when combined with EPDM rubber to produce cold-resistant hoses, can achieve quality assurance and cost reduction through reasonable formula design. So what are the issues to be aware of when designing hose formulations using EPDM/recycled rubber to produce cold-resistant hoses?

Generally, the vulcanized rubber compound will slow down slowly under low temperature conditions, and the hardness, modulus and internal friction of the molecule will increase, and the elasticity will decrease, resulting in a decrease in the working ability of the cold resistant hose (especially under dynamic conditions). Propylene rubber is a copolymer of ethylene, propylene and a small amount of non-conjugated diene. Non-polar rubber has low cohesive energy and no bulky side groups inside the molecule hinders molecular chain motion, especially in a wide range. The molecular chain flexibility and elasticity can be maintained in the condition; the EPDM reclaimed rubber retains most of the molecular structure characteristics of the EPDM rubber, and can be used in a suitable ratio with the EPDM rubber to produce a cost-effective cold-resistant hose.

When using EPDM/recycled rubber and producing cold-resistant hose, it can be vulcanized with peroxide, with carbon black, zinc oxide, stearic acid, antioxidant, clay, plasticizer, coupling agent, etc., among them: DCP It is the most commonly used vulcanizing agent in peroxide vulcanization system. When DCP and EPDM/recycled rubber are co-heated, cracking produces alkoxyl radicals, and the hydrogen atoms on the EPDM molecular chain are captured by the addition reaction of free radicals. The carbon-carbon cross-linking bond is formed during the reaction; the cross-linking agent VP-4 can further improve the vulcanization effect and the low mechanical index of the peroxide vulcanizate during the vulcanization of the peroxide.

Carbon black is the most reinforcing filler in the production of rubber products. Carbon black N550 is easy to disperse in the rubber compound, which can improve the stiffness, extrusion speed and surface smoothness of the EPDM vulcanizate. Rubber elastic, reinforcing and restorative; carbon black N990 has a small overall degree of aggregation and low structure, and can be used together to add EPDM/recycled rubber cold-resistant hose formula. Clay in EPDM rubber / reclaimed rubber and used in the production of cold-resistant hose formula can improve the processing properties of the rubber compound, increase the viscosity, stiffness and shrinkage of the cold-resistant rubber compound. The clay treated with the vinyl silane coupling agent is cold-resistant. The dispersibility in the rubber compound is better, the bonding performance between the clay and the rubber matrix interface can be improved, and the mechanical properties of the cold resistant hose can be further improved.

The compounding agent that affects the cold resistance of the EPDM cold-resistant hose is also a plasticizer. In the actual application process, the plasticizer can lower the glass transition temperature of the EPDM/recycled rubber, increase the flexibility of the rubber molecule, and reduce the molecular weight. Inter-force; plasticizer DOS is a non-volatile cold-resistant plasticizer that can greatly improve the cold resistance of EPDM cold-resistant hose.

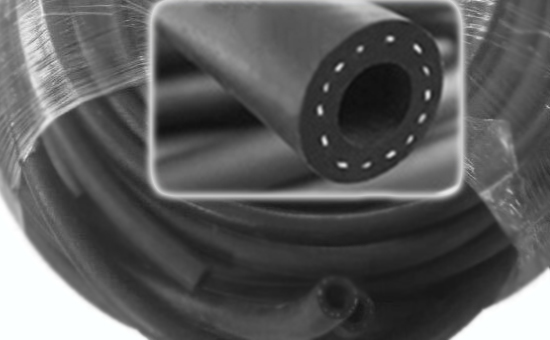

The cold-resistant hose produced by the combination of EPDM rubber and EPDM reclaimed rubber can be used as a circulating water pipe and connecting hose for the cooling system, and maintains good cold resistance, ozone resistance, aging resistance and resistance at low temperatures for a long time. Coolant and electric resistance, reasonable formula design can reduce the compression set and tensile strength of EPDM/recycled rubber hoses while reducing costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits