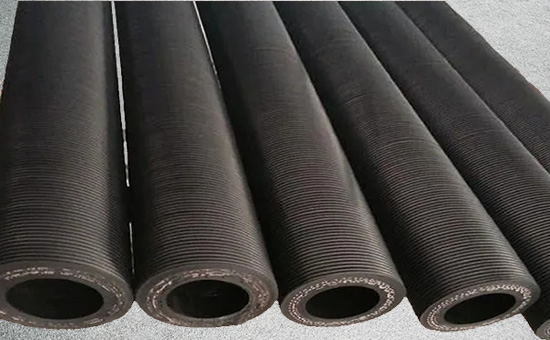

Mud pipe as an important conveying mud, mineral slurry, river sand and other materials of rubber pipeline, its inner wall rubber layer needs to have excellent oil resistance, wear resistance, heat resistance, the traditional production method is to use 26, N41, 3305 and other nitrile rubber production, raw material cost is very high. Due to the possible presence of a certain proportion of oily substances in the slurry, ordinary rubber materials are susceptible to corrosion during the slurry conveying process and lose their original elasticity and adhesion properties. HY nitrile reclaimed rubber can effectively resist the corrosion of oily substances, maintain its good physical properties, and ensure the normal operation of the pipeline. In recent years, many rubber pipe manufacturers have begun to experiment with the use of nitrile recycled rubber to replace part of the nitrile rubber to produce oil-resistant and wear-resistant mud pipe inner wall glue, which not only reduces costs and saves labor and electricity costs, but also improves the market competitiveness of products, and the market share increases year by year.

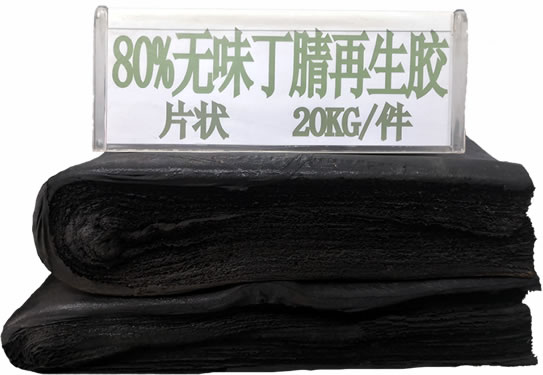

Nitrile regeneration rubber using waste nitrile gloves as the main raw material, by 100 mesh crushing, desulfurization, filtration, refining, the product oil resistance coefficient is large, feel elasticity, high fineness, no impurities, the surface of the product is smooth and bright, high plasticity, wear resistance, aging resistance is good. The molecular chain of nitrile regenerated rubber contains polar groups, which makes it have excellent oil resistance and can maintain good physical properties under high temperature, high pressure, grease and other conditions; It also contains a large number of branch chains, which make it have excellent wear resistance and can maintain good performance under high-speed, high-load conditions.

Vulcanization formulations are an indispensable part of the production of slurry tubes from nitrile regenerated rubber. Reasonable vulcanization formula can make nitrile regenerated rubber get the best physical properties in the vulcanization process, with excellent oil resistance and wear resistance. The following is an example of the vulcanization formula of the inner wall of the oil-resistant and wear-resistant mud pipe produced by Hongyun nitrile reclaimed rubber, for reference only:

Nitrile reclaimed rubber 20kg, 3305 nitrile rubber 7.5kg, N550 carbon black 2kg, light calcium carbonate 5kg, DOP3kg, CTP anti-scorch agent 0.7kg, RD antioxidant 0.2kg, stearic acid 0.5kg, paraffin 0.3kg, zinc oxide 0.7kg, CZ accelerator 0.1kg, DM accelerator 0.1kg, TMTD accelerator 0.07kg, sulfur 0.225kg; head temperature 60-80 °C, vulcanization temperature 145-150 °C, HYY(2)3718 vulcanization time is determined according to thickness.

The production of oil-resistant and wear-resistant mud pipe inner wall glue vulcanization formula of nitrile reclaimed rubber is a complex process, which requires the selection of appropriate raw materials for scientific proportioning and treatment. The reasonable vulcanization formula can make the nitrile reclaimed rubber have excellent oil resistance and wear resistance, and ensure the efficient and stable slurry transportation. Through continuous research and innovation, nitrile regeneration rubber will play an important role in the field of slurry conveying.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits