Recycled rubber is an environmentally friendly and sustainable material that is widely used in various industries. With the enhancement of environmental awareness and the importance of resource recycling, the production and application of nitrile recycled rubber have gradually attracted attention. The production of oil-resistant and wear-resistant rubber sheets produced by nitrile regenerated rubber has similar oil resistance and wear resistance to nitrile rubber, which is more environmentally friendly than nitrile rubber materials and has a large market application space.

Nitrile reclaimed rubber has the following characteristics

1、Nitrile regeneration rubber has excellent oil resistance and can be used stably in various oil media for a long time. Its molecular structure contains a nitrile group, which gives it high oil resistance and expansion resistance.

2、Nitrile reclaimed rubber has good wear resistance and can maintain excellent wear life in high friction environment. Due to the particularity of its internal structure, nitrile reclaimed rubber has high hardness and wear resistance, and can effectively resist damage caused by mechanical wear and friction.

3、Nitrile reclaimed rubber has good strength and acid and alkali resistance,nitrile reclaimed rubber material has high tensile strength, tear resistance and impact resistance, and can maintain stable performance under harsh working conditions such as ultraviolet rays, oxygen, ozone, acid and alkali solutions.

4、Nitrile recycled rubber as a recycled rubber material has significant environmental advantages. Hongyun nitrile recycled rubber uses waste rubber products as raw materials for recycling and reuse, effectively reducing the demand for natural resources and reducing environmental pollution. At the same time, the production process of nitrile recycled rubber can reduce energy consumption and carbon emissions compared to newly produced rubber materials.

HY nitrile reclaimed rubber production oil-resistant wear-resistant rubber sheet reference vulcanization formula:

Nitrile regenerated gum 25kg, N550 carbon black 5kg, light calcium carbonate 10kg, dibutyl ester 5kg, paraffin wax 0.4kg, CTP rubber anti-scorch agent 0.7kg, stearic acid 0.5kg, zinc oxide 0.8kg, CZ accelerator 0.1kg, M accelerator 0.1kg, TMTD accelerator 0.05kg, RD antioxidant 0.2kg, vulcanization 0.3kg, vulcanization temperature 150 °C, vulcanization time 25-35 seconds per mm. This recipe is for reference only, if it needs to be used in production, please adjust it according to the specific index performance of TT23/727 products.

It should be noted in the nitrile regeneration rubber mixing process: nitrile rubber is a polar rubber, easy to produce scorch in the process of mixing rubber, anti-scorching agent can be added in the mixing, and it is recommended to add antioxidants in advance when adding accelerator vulcanizing agent in the mill; Nitrile mixed rubber is controlled at about 80 °C as much as possible, so that the additives are evenly dispersed in the rubber material.

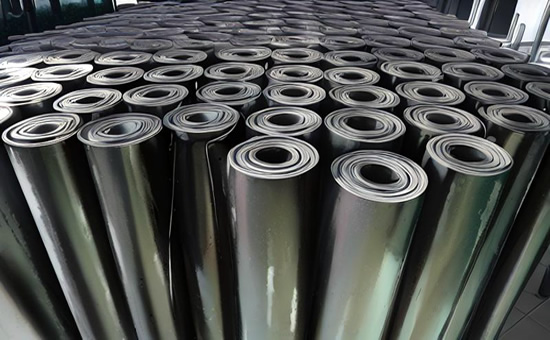

The oil-resistant and wear-resistant rubber sheet produced by nitrile reclaimed rubber has excellent oil, wear, weather resistance and other properties, and is suitable for various industrial fields that need to resist grease and withstand wear. Generally, rubber product enterprises use nitrile reclaimed rubber to produce rubber sheets, which is about 20% lower than the cost of nitrile rubber raw materials. By optimizing the formulation design and rubber refining process of nitrile regenerated rubber, oil-resistant and wear-resistant nitrile reclaimed rubber sheet can be produced, which can not only effectively save resources, reduce raw material costs, but also reduce the impact of waste on the environment.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits