The stable molecular chain structure and low unsaturation of EPDM rubber give the rubber excellent weather resistance. The EPDM reclaimed rubber processed from waste EPDM rubber and its products retains the basic performance characteristics of the original rubber and has weather resistance. Good, it can be used alone or in combination with EPDM to produce rubber products with strict requirements on weather resistance. In actual production, when using EPDM virgin rubber or EPDM reclaimed rubber to produce light-colored rubber products, rubber product manufacturers need to take appropriate measures to further improve the weather resistance of the finished product.

1. Factors affecting the weather resistance of light-colored EPDM products

When using EPDM rubber or reclaimed rubber to produce light-colored rubber products, the diene content of EPDM rubber, the physical properties of EPDM reclaimed rubber, the reinforcement filling system and the design of the antioxidant system 2YLYY31 will all affect the light-colored products. Weather resistance. Rubber product manufacturers need to choose appropriate EPDM/reclaimed rubber products and compounding agents, and rationally design light-colored EPDM product formulas to further improve the weather resistance of light-colored EPDM products.

2. Methods to improve the weather resistance of light-colored EPDM products

(1) Rubber selection: When using EPDM raw rubber to produce light-colored rubber products, EPDM rubber with a lower diene content has better weather resistance. When using EPDM reclaimed rubber in light-colored EPDM rubber products to reduce costs, it is more beneficial to choose environmentally friendly and non-migrating EPDM reclaimed rubber with high rubber content to improve the weather resistance of rubber products.

(2) Mixing agent selection: EPDM rubber with dark-colored reinforcing fillers such as carbon black has better UV shielding effect and better resistance to sunlight cracking, and EPDM rubber with light-colored reinforcing fillers and fillers is resistant to sunlight The cracking and aging performance is poor, and the anti-aging agent needs to be used in conjunction. Among them, it is best to choose non-polluting antioxidants, such as phenolic antioxidants, paraffin wax, etc., to improve the weather resistance of light-colored EPDM rubber products.

The yellowing and discoloration of rubber products are the result of electron transitions under the action of ultraviolet light. When improving the weather resistance of light-colored EPDM rubber products, pay attention to the yellowing resistance and discoloration of the rubber raw materials, avoid the use of light calcium, and choose non-polluting raw rubber, antioxidants, softeners and fillings that are not easy to yellow Agent.

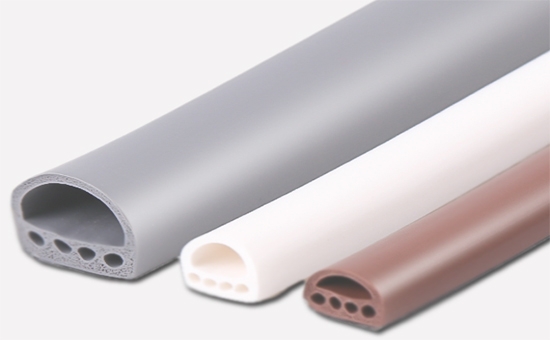

When using EPDM rubber or EPDM reclaimed rubber in light-colored EPDM rubber products such as white-gray sealing strips, you must choose EPDM virgin rubber/reclaimed rubber, and choose a suitable compounding system, especially filler , Anti-aging agent and softening agent, while reducing the cost, ensure the weather resistance of light-colored EPDM rubber products and prolong the service life of the products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits