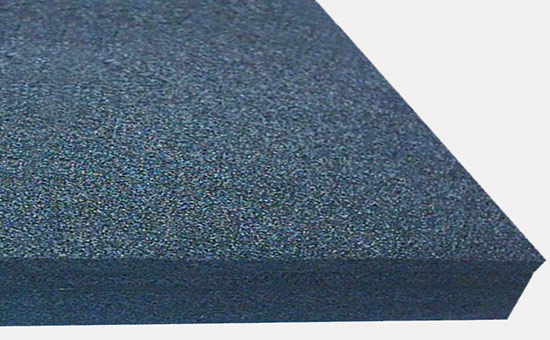

As a kind of porous vulcanized rubber, sponge rubber has excellent shock absorption, sound insulation and heat insulation properties, and has a wide range of applications in many fields. The performance of sub-brand natural rubber is close to that of standard natural rubber, and the price is much lower than that of standard rubber, so it is often considered for the production of sponge rubber. However, since the physical properties of sub-brand natural rubber may differ from the genuine one, there are several key requirements that need to be paid special attention to during the production process.

1. Strictly control the plastic refining process

The viscosity of the sub-brand natural rubber may be high, and it is recommended to use a three-stage or four-stage plasticizing method in the plastic refining process to ensure that the number of thin passes reaches 40 to 100 times, so as to reduce the viscosity of the raw rubber and improve its plasticity. After plastic refining, the sub-brand natural rubber rubber should be parked for at 2 to 7 days to promote the full dispersion of the compounding agent and avoid problems such as uneven hole size and bulging bubbles when manufacturing sponge rubber.

2. Pay attention to the matching of foaming and vulcanization rate

In the production of sponge rubber, the matching of foaming rate and vulcanization rate is the key technology. When designing the sponge rubber formula with sub-brand natural rubber as the main raw material, it is necessary to accurately calculate the dosage of foaming agent E4LYY14 and the composition of the vulcanization system to ensure that the foaming process is synchronized with the vulcanization process to obtain uniform pore structure and good physical properties.

3. Heat transfer of the compound

Good heat transfer is very important for the uniform foaming and vulcanization of sponge rubber, and the formula of sub-brand natural rubber sponge should be optimized in the production process, and appropriate processing aids should be added, which can effectively improve the heat transfer of the rubber and ensure that the internal and external bubble cells are uniform and the vulcanization degree is consistent.

4. Control the internal pressure of the rubber compound during foaming

In the foaming process, the pressure generated inside the rubber should be greater than the external pressure to ensure the stability of the foaming and the uniformity of the bubble holes.

5. Consider the design formulation holistically

When using sub-brand natural rubber to prepare sponge rubber, the formula design should comprehensively consider the type, size and uniformity of the holes, as well as the physical properties of the rubber, such as density, hardness, feel, softness, surface condition, etc., to meet the performance requirements of specific application scenarios.

Sub-brand natural rubber is an ideal raw material for replacing natural rubber to produce high-performance and low-price sponge rubber, which requires strict control and optimization in key process links such as plasticizing, foaming and vulcanization. Through reasonable formula design and process adjustment, we can make full use of the cost advantage of sub-brand natural rubber to ensure that the performance of the finished product meets the industry standard.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits