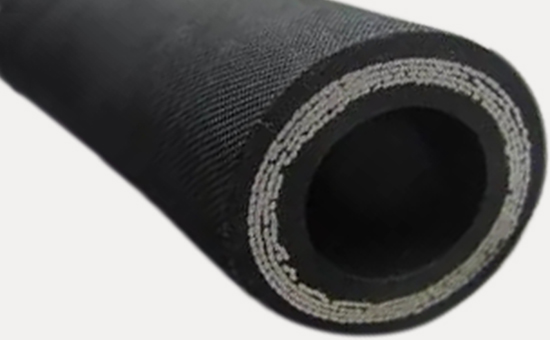

Ordinary fiber braided hose is composed of an inner rubber layer, a fiber braid layer and an outer rubber layer, which has the characteristics of lightness, softness, and low pressure deformation. Natural rubber has excellent mechanical strength and resilience, but poor oil resistance and aging resistance, and is often used in combination with styrene-butadiene rubber and other synthetic rubber to produce ordinary filament winding hoses that have no special requirements for oil resistance and chemical resistance. However, the price of natural rubber on the market is high and the price fluctuates greatly, so many companies have set their sights on reclaimed rubber.

So can the ordinary fiber braided hose produced by natural rubber be mixed with reclaimed rubber? Which reclaimed rubber is more suitable for weaving hoses with natural rubber to produce fibers?

1. Latex reclaimed rubber

Latex reclaimed rubber is processed from waste natural rubber and waste latex products as the main raw materials, with high strength, good elasticity and small specific gravity, with the basic performance characteristics of natural rubber, good compatibility with natural rubber, and can directly replace the appropriate proportion of natural rubber to produce the inner and outer rubber 2SLYY1030 layers of ordinary fiber woven hoses, effectively reducing the cost of raw materials. The latex reclaimed rubber on the market is mainly white and black latex reclaimed rubber, as well as green latex reclaimed rubber, red latex reclaimed rubber, etc.

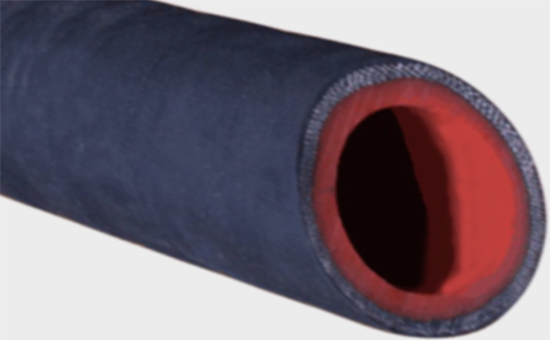

When natural rubber/styrene-butadiene rubber is used together to produce the outer rubber of red fiber woven hose, rubber product manufacturers can use white latex reclaimed rubber or red latex reclaimed rubber, which is easy to match color and not easy to change color.

2. Tire reclaimed rubber

Tire reclaimed rubber is processed from waste tires as the main raw material, and its main components are natural rubber, synthetic rubber (mainly styrene-butadiene rubber, butadiene rubber) and carbon black, which has good compatibility with natural rubber and styrene-butadiene rubber; High-quality tire reclaimed rubber has the performance characteristics of high strength, high elasticity, high wear resistance, tear resistance, etc., and can be used in combination with natural rubber and styrene-butadiene rubber to prepare the inner and outer rubber layers of ordinary fiber woven hoses, effectively reducing the cost of raw materials.

When tire reclaimed rubber is used instead of raw rubber, generally 100 parts of tire reclaimed rubber can be used instead of 30 parts of raw rubber.

In actual production, the inner and outer rubber layers of some ordinary fiber woven hoses can also use an appropriate amount of rubber shoe reclaimed rubber. When using reclaimed rubber to replace part of the natural rubber to produce each rubber layer of fiber hose, rubber pipe manufacturers need to adjust the formula appropriately, and the components in the reclaimed rubber except rubber hydrocarbons can be regarded as fillers and softeners, so the amount of active agents, antioxidants, fillers, softeners and other compounding agents in the hose formula containing reclaimed rubber can be appropriately reduced, and the amount of vulcanizing agent can be appropriately increased.

The use of reclaimed rubber to replace part of the raw rubber to produce the inner and outer rubber layers of fiber woven hoses can not only reduce the cost of raw materials, but also improve the performance of rubber processing technology.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits