Knowledge

-

Vulcanization is a process in which the rubber compound forms a three-dimensional network structure through intermolecular cross-linking of the raw rubber. The vulcanization system directly affects the finished…

-

When using chlorinated butyl reclaimed rubber to produce shock-absorbing rubber and other products, the requirements for the flexural resistance of the rubber are strict, so what measures can manufacturers take…

-

When EPDM rubber and EPDM reclaimed rubber are used together to produce rubber products, the mixing process is mostly carried out in an internal mixer, and the variety and amount of rubber additives directly af…

-

The rubber tube is a tubular rubber product processed from rubber as the main raw material for conveying various solids, liquids and gases. Adding an appropriate amount of vulcanized rubber powder can effective…

-

Cuando se utiliza caucho EPDM recuperado para producir productos de caucho, los agentes de refuerzo, los rellenos, los suavizantes, los plastificantes y los aceleradores juegan un papel insustituible. La disper…

-

When using EPDM reclaimed rubber or ethylene-propylene rubber/reclaimed rubber to produce rubber products, sufficient mixing is the basis for the smooth progress of the subsequent processes, so it is necessary …

-

In actual production, a large part of sponge rubber is processed with natural rubber as the main raw material. Latex reclaimed rubber can replace a certain proportion of natural rubber to produce sponge rubber,…

-

Reclaimed rubber and reclaimed rubber powder are renewable resources for the recycling and processing of waste rubber products. They have the basic performance characteristics of rubber and are low in price. Th…

-

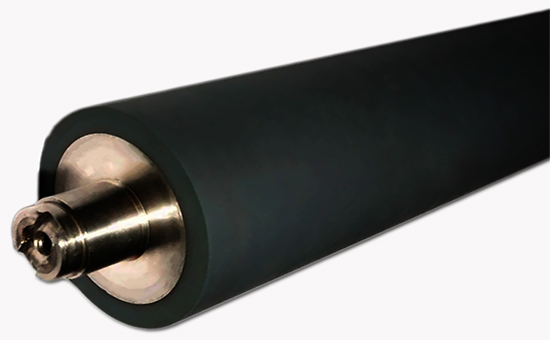

Nitrile reclaimed rubber can be used alone or in combination with nitrile rubber to produce various types of rubber rollers; rational design of formula can reduce more costs on the premise of ensuring the quali…

-

When using butyl rubber / reclaimed rubber to produce rubber inner tube, the reasonable use of reinforcing agent and softener can further improve the process performance of rubber, improve the quality of finish…

-

The covering rubber of canvas core heat-resistant conveyor belt requires that the rubber material has excellent heat-resistant performance. It is generally processed with styrene butadiene rubber or EPDM as the…

-

The inner rubber of the coreless cloth clamping hose in the cloth clamping hose is mainly processed with natural rubber, cis-1,4-butadiene rubber and styrene butadiene rubber as the main raw materials. A large …

-

The interlayer of the nylon rubber conveyor belt is nylon canvas. The quality of the nylon canvas rubber directly affects the performance and life of the rubber conveyor belt. Today, Xiaobian will share with yo…

-

Natural latex reclaimed rubber can directly replace natural rubber or be used in combination with natural rubber and general synthetic rubber to produce rubber products. When choosing latex reclaimed rubber, at…

-

The bead wire ring of the car tire is composed of a wire ring and a filler, so that the tire can be tightly fixed on the rim and withstand the interaction force among the tire and the rim; the gasket is to prot…

-

In actual production, most of the rubber surfaces of table tennis rackets are processed with natural rubber as the main raw material; natural latex reclaimed rubber, as a low-cost replacement material for natur…

-

Nitrile reclaimed rubber retains the basic performance characteristics of nitrile rubber, and can replace an appropriate amount of nitrile raw rubber to produce rubber products, effectively reducing the cost of…

-

The performance of retreaded tire tread rubber is directly related to the overall performance of the tire. Generally, it is processed from natural rubber as the main raw material. The appropriate amount of rubb…

-

In order to improve production efficiency, reclaimed rubber products are prone to scorch when the operating temperature of kneading, calendering, etc. is increased, or a high-temperature rapid vulcanization sys…

-

Rubber waterproof materials can effectively prevent rain, snow and water from infiltrating into buildings. Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, and can replace a…