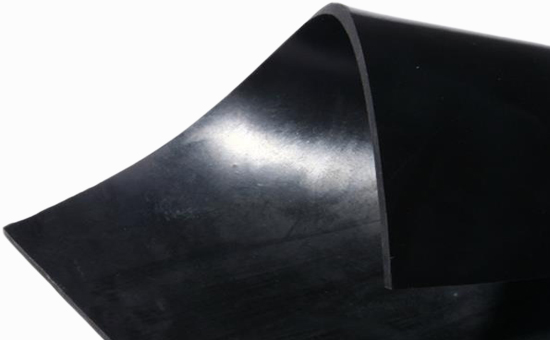

EPDM reclaimed rubber can directly replace high-priced EPDM raw rubber in the production of various rubber products, and the finished product maintains good performance. In actual production, EPDM reclaimed rubber is often used in the production of heat-resistant rubber sheets. It can be used to produce heat-resistant rubber sheets alone, or used in combination with EPDM rubber in an appropriate ratio to ensure the physical properties of heat-resistant rubber sheets. Under the premise of effectively reducing the cost of raw materials.

Reference formula for producing heat-resistant rubber sheet from EPDM rubber: 100 parts EPDM rubber, 1 part antioxidant D, 80 parts semi-reinforcing carbon black, 40 parts paraffin oil, 7 parts DCP, 1.3 parts TAC; in total, 229.3 copies.

1. Usage of EPDM reclaimed rubber in heat-resistant rubber sheet

EPDM reclaimed rubber retains the basic performance characteristics of the original EPDM rubber, high and low temperature resistance, ozone resistance, and has a good blending effect with EPDM rubber. It can be used with EPDM rubber to produce heat-resistant rubber sheets. In actual production, the mixing amount of EPDM reclaimed rubber 2YLYY84 in the heat-resistant rubber sheet needs to be determined according to the physical requirements of the rubber sheet and the basic indicators of the reclaimed rubber. Some heat-resistant rubber sheets can even use EPDM reclaimed rubber completely, effectively reducing Raw material costs.

2. Selection skills of vulcanizing agent for heat-resistant rubber sheet containing reclaimed rubber

When using EPDM reclaimed rubber alone or EPDM/reclaimed rubber combined with rubber to produce heat-resistant rubber sheets, peroxide vulcanization is generally selected, and DCP is more common. Using DCP vulcanized EPDM vulcanizate to generate carbon-carbon cross-linked bonds, high bond energy, good heat resistance and compression set of the vulcanizate. After DCP vulcanizate is combined with the auxiliary crosslinking agent TAC, it can increase the vulcanization rate, crosslinking degree and crosslink density, and improve the comprehensive physical properties of heat-resistant rubber vulcanizates containing reclaimed rubber.

3. Selection of other compounding agents for heat-resistant rubber sheets containing reclaimed rubber

When using EPDM reclaimed rubber or EPDM/reclaimed rubber combined to produce heat-resistant rubber sheets, it is recommended to use semi-reinforced carbon black. Semi-reinforcing carbon black belongs to soft carbon black, which has the dual functions of reinforcement and filling, and can give the compound high elongation, low heat generation, high elasticity and good aging resistance. Paraffin oil has a high flash point, low volatile content and low aromatic content. It can effectively prevent the aging and shrinkage of the rubber sheet when used in the production of heat-resistant rubber sheets. Anti-aging agent D has a good protective effect on heat, oxygen, flexion and general aging.

When using EPDM reclaimed rubber to fully or partially replace EPDM raw rubber to produce heat-resistant rubber sheets, the rubber sheet manufacturer must select the appropriate EPDM reclaimed rubber according to actual needs, and reasonably determine the ratio of reclaimed rubber to virgin rubber. , Appropriately adjust the rubber product formula to further optimize the quality of the finished product while reducing the production cost of heat-resistant rubber sheet.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits