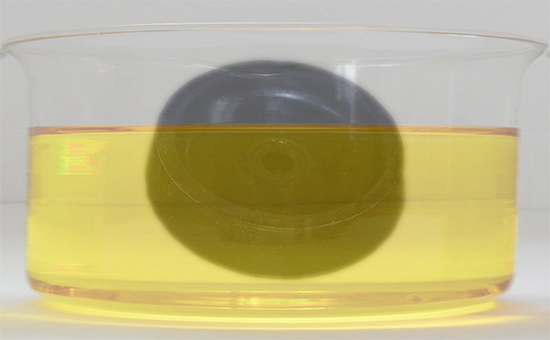

The rubber type, nitrile rubber is the best oil resistance, waste nitrile rubber products as raw material production of nitrile rubber reclaimed rubber is the best renewable rubber, it is widely used instead of nitrile rubber Production of a variety of oil-resistant rubber products such as oil-resistant rubber shoes, oil-resistant plastic sheet, oil seals, etc., to reduce the cost of raw materials for the purpose of the product; However, renewable nitrile rubber, after all, is the recycling of waste rubber resources, regeneration process lost part of the oil resistance , So instead of nitrile rubber production of high rubber products, the oil resistance to be improved.

There are three ways to improve the oil resistance of nitrile rubber products:

First, choose high-quality butyronitrile reclaimed rubber. The nitrile rubber oil resistance is determined by the acrylonitrile content, while the nitrile rubber reclaimed oil size is not only related to the acrylonitrile content, but also with the reclaimed rubber itself gel content has a certain relationship, usually containing more plastic volume High nitrile rubber reclaimed rubber oil performance better. Therefore, the choice of high acrylonitrile content, high content of nitrile rubber reclaimed rubber is to ensure that nitrile rubber products reclaimed with excellent oil resistance basis.

Second, we choose a vulcanization system that can improve the crosslinking density of the rubber of nitrile rubber. The higher the crosslinking density is, the better the oil resistance of the crosslinked nitrile rubber is. In the actual production, lead oxide or resin can improve the cross-linking density of rubber compound, so as to improve the oil resistance of rubber product.

Third, the production of oil-resistant rubber products, there will always be traces of plasticizers, however, too much plasticizer dosage will affect the performance of nitrile rubber reclaimed rubber, so in the design of reclaimed nitrile rubber formulations, the conditions If possible, try to reduce the amount of plasticizer, or use is not easy to be oil extracted polyester, liquid rubber, chlorinated polyethylene and other low molecular weight polymers as a plasticizer, so as to improve the performance of nitrile rubber reclaimed rubber products .

More ways to improve the nitrile reclaim adhesive waiting for us to jointly study, do you have any suggestions? However, regardless of the use of various ways to improve the oil resistance of nitrile reclaimed rubber products, it should be based on the use of nitrile rubber reclaimed rubber excellent performance of oil resistance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits