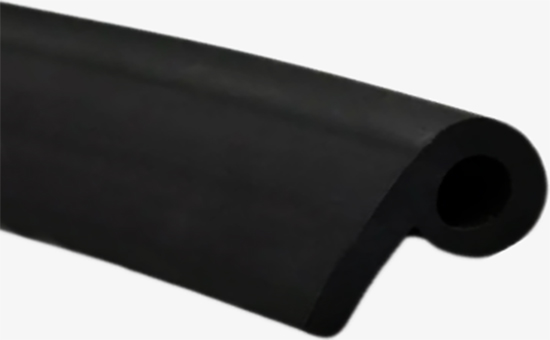

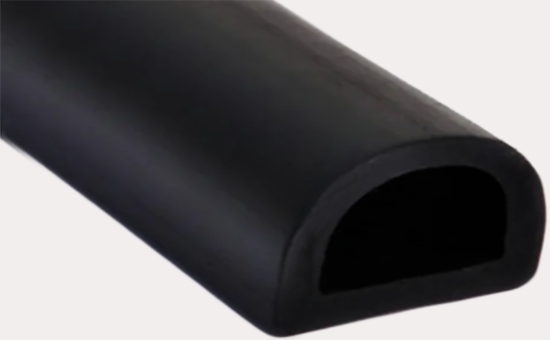

EPDM reclaimed rubber has excellent high and low temperature resistance, ozone resistance, weather resistance and other characteristics. It can be used alone or in combination with EPDM original rubber to produce rubber sealing strips, hoses, waterstops, conveyor belts, insulating materials, and wires. Cable sheaths, etc., reduce the cost of raw materials on the premise of ensuring product quality. When using EPDM reclaimed rubber as the main raw material to produce rubber products, the manufacturer must strictly control the production process.

1. The processing process of EPDM reclaimed rubber products - plasticizing

Plasticizing is a process in which the rubber macromolecules undergo chain scission and oxidative cracking through mechanical action, so that the raw rubber is transformed from a strong and elastic state to a soft and plastic state. Provide good conditions for subsequent processing and molding. EPDM reclaimed rubber 2ELYY914 itself has good fluidity and high plasticity; the plasticity of EPDM rubber is about 0.2-0.5, which is suitable for mixing and processing requirements. Therefore, when using EPDM reclaimed rubber or EPDM/EPDM reclaimed rubber to produce EPDM rubber products, the manufacturer can directly mix it without masticating.

2. EPDM reclaimed rubber product processing process - mixing

(1) Mixing method: Mixing is an important process in the production of EPDM reclaimed rubber products. The function of mixing is to completely and uniformly disperse various compounding agents in the raw rubber, which directly affects the quality of the finished product. The mixing process equipment of EPDM reclaimed rubber includes open mill and internal mixer.

When EPDM reclaimed rubber is mixed in an open mill, it is mainly divided into three stages: wrapping rolls, eating powder and turning over; The order of addition affects the quality of the compound. When the EPDM reclaimed rubber is mixed in the internal mixer, the mixing process is divided into three stages: wetting, dispersion and kneading; the filling capacity, the pressure of the top bolt, the rotor speed and mixing time, and the mixing temperature will affect the three stages. EPDM reclaimed rubber compound quality.

When EPDM reclaimed rubber is mixed in an open mill, the usual feeding sequence is masticating rubber, EPDM reclaimed rubber, masterbatch → accelerator, active agent, antioxidant → reinforcing agent , filler → liquid softener → sulfur, super speed accelerator. When the EPDM reclaimed rubber is mixed in the internal mixer, the feeding sequence is EPDM reclaimed rubber → active agent, solid softener, anti-aging agent, common accelerator, anti-scorch agent → carbon black → liquid softener → sulfur and overspeed accelerator.

(2) Selection of compounding agents: When using EPDM reclaimed rubber to produce rubber products, a reasonable selection of compounding agents can further improve the processing performance of rubber materials and the performance and life of finished rubber products, mainly including vulcanizing agents, accelerators, softeners. , antioxidants, reinforcing agents, fillers, colorants and special additives for special purposes, etc.

EPDM reclaimed rubber products can use super-speed accelerators such as tetramethylthiuram monosulfide, disulfide, or metal dithiocarbamate, and use thiazoles as co-accelerators; zinc oxide is a commonly used active agent ; Vulcanizing agent is commonly used peroxide and sulfur, heat-resistant rubber products use less or no sulfur. Wear-resistant carbon black is a commonly used reinforcing agent for EPDM reclaimed rubber products. Clay, silica, and talc have a certain reinforcing effect in EPDM. Commonly used softeners for EPDM reclaimed rubber products include naphthenic oil, paraffin oil, aromatic oil, etc. Commonly used antioxidants for EPDM reclaimed rubber products include antioxidants RD, BLE, 264, 2246, MB, etc.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits