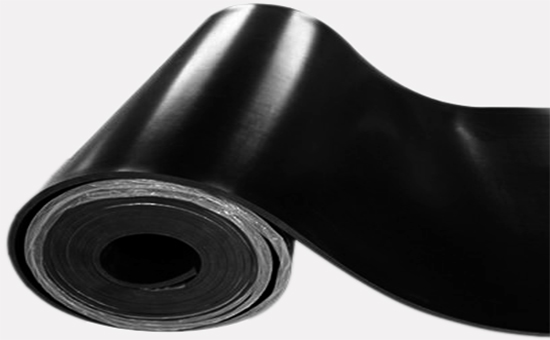

Rubber sheet is a sheet-like rubber product with a certain thickness and a large area, which is processed from rubber as raw material, and is widely used in industrial and mining enterprises, transportation and other fields. Natural rubber has good elasticity and high mechanical strength, and is an ideal raw material for the production of various types of rubber sheets. However, the price of natural rubber is high and fluctuates greatly, which causes rubber sheet manufacturers to face great cost pressure; as a new raw material to replace high-priced raw rubber, reclaimed rubber can be used together with natural rubber to produce rubber sheets, which can reduce the cost of rubber sheets on the premise of ensuring the quality of the rubber sheets. Cost of production.

In actual production, the combination of natural rubber/reclaimed rubber can produce ordinary rubber sheets, acid and alkali resistant rubber sheets, insulating rubber sheets, wear-resistant rubber sheets, etc. Reasonable mixing of reclaimed rubber and proper adjustment of the formula can further improve the quality of rubber sheets , reducing further costs.

1. Skills of producing ordinary rubber sheets with natural rubber/reclaimed rubber

Reclaimed rubber can be used alone or in combination with natural rubber in ordinary rubber sheets to improve the performance of rubber sheets. In actual production, it is recommended to use a sulfur-accelerator system to produce ordinary rubber sheets with natural rubber/reclaimed rubber combined, and use accelerator M, accelerator DM or accelerator D with sulfur; it is recommended to use calcium carbonate, clay, Barite powder and carbon black are used together; softeners such as engine oil and coumarone resin are used to adjust the hardness of the rubber sheet and the technical performance of the rubber compound.

2. Skills of producing acid and alkali resistant plywood with natural rubber/reclaimed rubber

Natural rubber can be used to produce ordinary acid and alkali resistant rubber sheets. The proper use of reclaimed rubber such as tire tread reclaimed rubber 2ELYY810 in the formulation of acid and alkali resistant rubber sheets produced with natural rubber as the main raw material can effectively reduce the cost of raw materials. When natural rubber/reclaimed rubber is used to produce acid and alkali resistant rubber sheets, try to use a sulfur-accelerator system with high vulcanization crosslinking density, and the amount of sulfur can be increased to about 5 parts; the use of clay, barium sulfate, talc, etc. has chemical Inert substances are used as fillers, avoiding the use of compounds with poor acid resistance such as calcium carbonate and magnesium carbonate.

3. Techniques for producing insulating rubber sheets with natural rubber/reclaimed rubber

Natural rubber can be used to produce low-voltage insulating rubber sheets. When natural rubber is used as the main raw material to produce insulating rubber sheets, latex reclaimed rubber or tire reclaimed rubber can be used to replace a certain proportion of natural rubber to reduce the production cost of insulating rubber sheets. To design the formula of natural rubber/reclaimed rubber insulating rubber sheet, it is recommended to use accelerator M, accelerator DM, accelerator D and sulfur for vulcanization system; carbon black and clay, talc, calcium carbonate, etc. with low structural degree are used for reinforcing filling system; The softener can be used together with paraffin and coumarone; adding amine or p-phenylenediamine antioxidants can improve the heat resistance of insulating rubber sheets, and anti-aging agent H can also improve the insulating properties of rubber compounds.

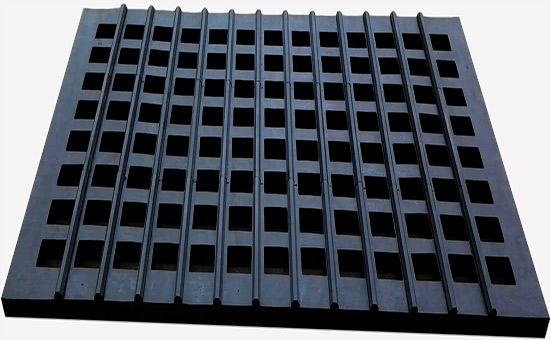

4. Techniques for producing wear-resistant rubber sheets with natural rubber/reclaimed rubber

Wear-resistant rubber sheet has the characteristics of high wear resistance, good elasticity and low noise, and is widely used in coal, metallurgy, chemical industry, building materials, mining and other industries. to make. Latex reclaimed rubber with high rubber content and high-strength tire tread reclaimed rubber have high mechanical strength, good elasticity, and excellent wear resistance. They can be mixed with natural rubber or natural rubber/styrene-butadiene rubber to produce wear-resistant rubber sheets.

When designing the formula of natural rubber/reclaimed rubber wear-resistant rubber sheet, generally follow the guidelines of high wear resistance, high strength, moderate elasticity and good processing performance. Natural rubber/reclaimed rubber wear-resistant rubber sheet can be vulcanized with sulfur, accelerator CZ/DM can be used together, and a small amount of accelerator TMTD can be used for adjustment; the reinforcing filling system can use high wear-resistant carbon black, medium and super wear-resistant carbon black, etc., which can effectively improve wear resistance. Mechanical strength and wear resistance of rubber sheets.

In actual production, latex reclaimed rubber and tire reclaimed rubber in reclaimed rubber products have good compatibility with natural rubber, and can be used together with natural rubber to produce ordinary rubber sheets, acid and alkali resistant rubber sheets, insulating rubber sheets, wear-resistant rubber sheets, etc. , the editor will continue to share with you the specific formula and production process points of natural rubber/reclaimed rubber combined with rubber to produce various types of rubber sheets.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits