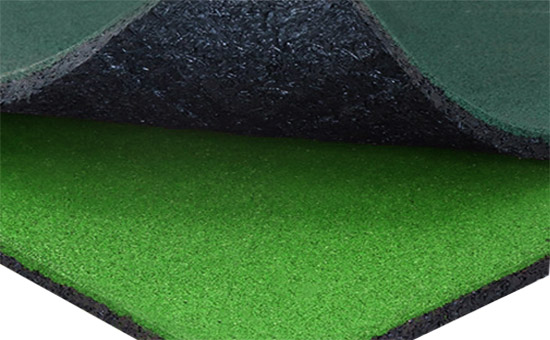

Rubber floor tiles have the characteristics of wear resistance, weather resistance, anti-skid, shock absorption, anti-static, non-reflective, etc., and have good hydrophobicity and long service life during use. In actual production, traditional rubber floor tiles are generally processed with natural rubber as the main raw material; but the price of natural rubber is high and the price fluctuates greatly, so many rubber floor tile manufacturers have begun to pay attention to reclaimed rubber, reclaimed rubber powder and other rubber regeneration. resource. So can recycled rubber and recycled rubber powder be used in the production of rubber floor tiles? How much is appropriate to mix?

1. Techniques for mixing latex reclaimed rubber and tire reclaimed rubber with rubber floor tiles

In actual production, the rubber floor tiles produced with natural rubber as the main raw material can be mixed with latex reclaimed rubber or tire reclaimed rubber in an appropriate amount. Latex reclaimed rubber with high rubber content can completely replace natural rubber to produce rubber floor tiles, effectively reducing the cost of raw materials on the premise of ensuring product quality. For example, 100% white latex reclaimed rubber can replace natural rubber in a 1:1 ratio to produce colored rubber floor tiles . Black rubber floor tiles can be mixed with black latex reclaimed rubber or tire reclaimed rubber, and the production cost is lower; 100 parts of tire reclaimed rubber is equivalent to 30 parts of raw rubber.

2. Rubber floor tiles are mixed with tire rubber powder to reduce costs

Tire rubber powder is mostly used as a filler material in the production of rubber floor tiles with natural rubber as the main raw material, which further improves the wear resistance and low temperature flexibility of rubber floor tiles while reducing costs. Tire rubber powder 2ELYY727 can also be used as the main material in the production of rubber floor tiles. 100 parts of tire rubber powder can be directly mixed and formed with 2-3 parts of sulfur, 1 part of accelerator and other processing aids. The finished product has Good cushioning, slip resistance, water permeability and a certain thermal insulation effect.

3. Reference formula for natural rubber + latex reclaimed rubber production of rubber floor tiles

50 parts of natural rubber, 50 parts of 100% latex reclaimed rubber, 10 parts of zinc oxide, 1.5 parts of stearic acid, 2 parts of paraffin, 1 part of softener, 270 parts of clay, 50 parts of heavy calcium, 25 parts of titanium oxide, 4 parts of sulfur , 1.5 parts of accelerator; total: 465 parts.

4. Reference formula for natural rubber + tire reclaimed rubber to produce rubber floor tiles

50 parts of natural rubber, 150 parts of tire reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of antioxidant A, 3 parts of paraffin wax, 45 parts of carbon black N330, 90 parts of heavy calcium, 30 parts of motor oil, accelerator CZ 1.5 parts, 4 parts of sulfur; total: 382 parts.

The rubber floor tiles produced with natural rubber as the main raw material are reasonably mixed with latex reclaimed rubber, tire reclaimed rubber or tire rubber powder, which can not only ensure product quality, but also reduce raw material costs. In actual production, rubber product manufacturers can also add a small amount of styrene-butadiene rubber to the formula of rubber floor tiles containing reclaimed rubber or reclaimed rubber powder to further improve the wear resistance of rubber floor tiles, etc. The editor will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits