Nitrile reclaimed rubber can replace various nitrile rubber to produce various oil-resistant rubber products. It can resist the aging phenomenon in oil medium for a long time, and it has good resistance to oil. The molecular structure of nitrile reclaimed rubber is not easily affected by oil. Impact; rubber oil can improve the viscoelasticity of rubber compound and improve the process performance of recycled rubber products during the processing of recycled rubber products, but the nitrile reclaimed rubber is not "cold" for many oils, how should the rubber oil in the softening system be? select?

Nitrile rubber is prepared by emulsion polymerization of butadiene and acrylonitrile. Typical polar rubber has good resistance to non-polar and weakly polar oils and solvents. The higher the acrylonitrile content, the nitrile rubber The better the oil resistance; the nitrile reclaimed rubber retains the basic performance characteristics of the nitrile rubber, so many rubber oils do not play the role of softening and plasticizing in the nitrile reclaimed rubber products.

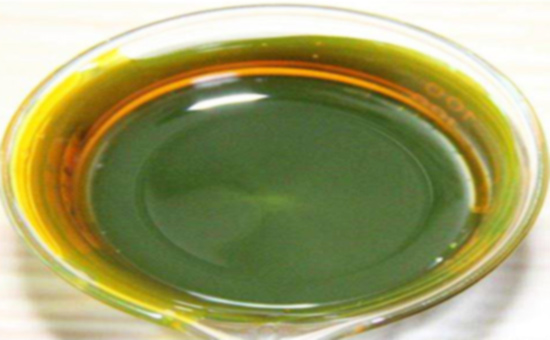

When rubber oil must be used in the processing of nitrile reclaimed rubber products, petroleum-based aromatic hydrocarbon-based rubber oil can be used. The aromatic content should be higher than 50%-60%, improve the processing properties of butyl reclaimed rubber, promote the dispersion of compounding agents, and increase the nitrile. Recycled rubber products have tensile strength, high and low temperature resistance, and weathering resistance and oxidation resistance. Paraffin oil and naphthenic oil are generally not recommended. Naphthenic oil can prolong the scorch time in the production of rubber products. When using naphthenic oil, attention should be paid to the amount of naphthenic oil to avoid excessive use of rubber oil and reduce the recovery of nitrile. The mechanical strength problem of the vulcanizate appears.

When using nitrile reclaimed rubber to produce rubber products, there are not many rubber oils that can be used, and the amount should be controlled. Therefore, the nitrile rubber compound uses ester plasticizers such as phthalates, sebacates, etc. , follow the similar compatibility principle to reduce the viscosity of the rubber compound and improve the process performance of the nitrile reclaimed rubber product.

There are many varieties of nitrile reclaimed rubber on the market. The indexes of nitrile reclaimed rubber produced by different raw materials and different manufacturers are obviously different. The higher the gel content, the closer the molecular structure of nitrile reclaimed rubber and nitrile rubber. The higher the viscosity, so it will encounter great problems during processing, which limits the use range of nitrile reclaimed rubber; rational use of rubber oil and ester plasticizer in nitrile reclaimed rubber products to improve nitrile reclaimed rubber Processing technology performance, expand the use range of nitrile reclaimed rubber products, reduce more production costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits