In the production process of rubber products, the peptizer can enhance the plasticizing effect of the raw rubber by chemical action, thereby shortening the mastication time and improving the production efficiency; when the waste rubber and waste rubber products are processed into reclaimed rubber, the peptizer is also It can be used as a regenerative activator for waste rubber; compared with the original rubber, the reclaimed rubber has good fluidity, high plasticity, and even no need for mastication. Is it necessary to add the peptizer again during the processing of the reclaimed rubber product?

Peptizers can be classified into physical peptizers and chemical peptizers. The chemical peptizer can be used as an oxidation catalyst in rubber. Firstly, the peptizer itself decomposes into free radicals under the action of heat and oxygen, and oxidatively degrades the rubber molecules; then the rubber chain ends of the broken chains are lost during the closed mastication. The activity prevents the free radicals from agglomerating again; usually, the greater the free radical ability of the peptizer, the greater the peptizing ability, and the plasticizing effect of the chemical peptizer increases as the reaction temperature increases. Physical peptizers use the lubrication between macromolecules to reduce the Mooney viscosity of the rubber and improve the plasticity and fluidity of the rubber.

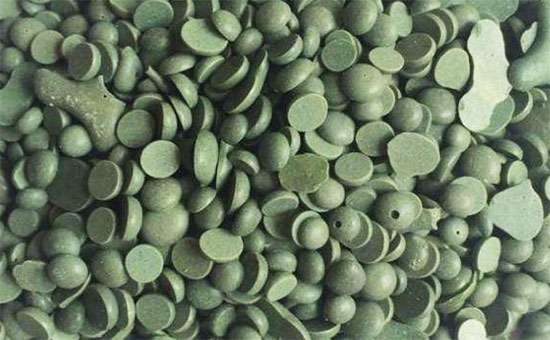

Recycled rubber is a product of waste rubber products. Although it is superior in plasticity and fluidity to natural rubber and synthetic rubber, it is necessary to use an appropriate amount of peptizer under certain conditions, especially when used together with original rubber; different types The peptizer has different effects in the reclaimed rubber. Different reclaimed rubber products require different types and different amounts of peptizers.

When using latex reclaimed rubber, isoprene reclaimed rubber or latex reclaimed rubber and natural rubber, styrene-butadiene rubber and isoprene rubber to produce rubber products, 2-naphthylthiophenol peptizer can be used to promote the addition of thiazole. The natural rubber compound of thiuram and thiuram accelerator has activation effect, good dispersibility in rubber, no pollution, no irritating odor, and does not affect the mechanical properties and aging resistance of reclaimed rubber products; In addition to the same effect as 2-naphthylthiophenol, the above-mentioned rubber compound has a stabilizing effect on the viscosity of the cement.

Pentachlorothiophenol can also be used in the production of latex reclaimed rubber and nitrile reclaimed rubber products, but it is replaced by other types of peptizers due to the possibility of toxic substances.

In short, the question of whether or not a peptizer can be used in the production of recycled rubber products is not simply a “yes” or “no” answer. There are many peptizer products commonly used in the rubber products industry. According to the performance requirements of recycled rubber products and the testing indicators of raw materials, it is finally decided whether to use peptizers and select peptizer products that can achieve the best plasticizing effect.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits