Rubber softener that is rubber-filled oil, rubber processing can improve performance: reduce the consumption of mixing power and promote the uniform dispersion of various accessories to improve the elongation of the vulcanized rubber elasticity. Reclaimed rubber as a widely used type of rubber, in the production and processing are also inseparable from the softener. This small series to introduce you to several commonly used plastic regeneration agent.

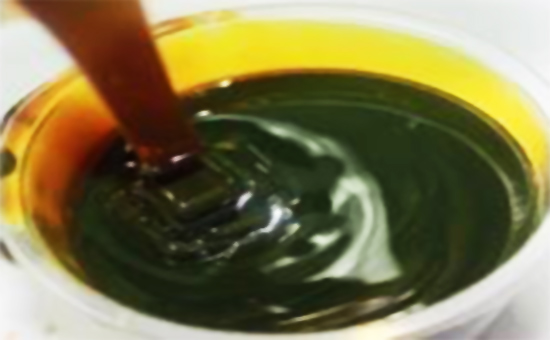

1, Coal Tar: Coal tar belongs to the by-product of coal-based softener and coal-refining glue for coking plant. It mainly consists of phenols, alkyl aromatic hydrocarbons, naphthalene, anthracene, pyridine and asphalt. , Irritating odor, can not make light-colored products. Coal-based softeners also include coumarone resins, coal tar pitch and the like. The country has banned reclaimed rubber from using coal tar as a softener.

2, pine tar and rosin: Pine tar and rosin belong to the softener of vegetable oil system. Pine tar is the product of the pine root and trunk after retorting, mainly composed of resin acid. The regenerated rubber produced by using pine tar has good processibility and Physical and mechanical properties, the general tasteless reclaimed rubber used in this softener; rosin from the resin pine resin processing, the main ingredient is rosin acid and rosin acid anhydride, can improve the regeneration of adhesive and anti-aging properties, commonly used in tire reclaimed rubber. Vegetable oil softener also includes turpentine, rosin cracked oil, pine softdown oil, litsea cubeba oil, terpene and other products.

3, tall oil: green tall oil, also known as liquid rosin, is derived from the alkaline method (mainly kraft) residual black solution obtained when the wood pulp, mainly resin acid, fatty acid each about 40% Easy to layer in the storage and precipitation of rosin, when used by heat treatment, the use of non-stick process roller, due to the low degree of pollution for the production of environmentally friendly recycled plastic.

In addition, the commonly used softener reclaimed rubber also synthetic systems of dibutyl phthalate, dioctyl phthalate, dibutyl sebacate, dioctyl sebacate, higher fatty alcohols, higher fatty acids and Petroleum oil, residual oil, petroleum resin, petroleum bitumen, Xiaobian not one by one.

Reclaimed rubber production and processing process using softener has two main roles:

1, infiltration and expansion effect. Low-boiling substances in the regeneration process can penetrate in the rubber molecules, at the same time as a result of expansion of the heat between the rubber molecules and the filler between the weakening of the interaction force, increasing the distance between the molecules to reduce the structural possibilities;

2, thickening plastic effect. High boiling point after high temperature desulfurization can remain in the rubber compound to increase the viscosity and plasticity role.

Different types of softeners play different roles in reclaimed rubber products. Are you right?

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits