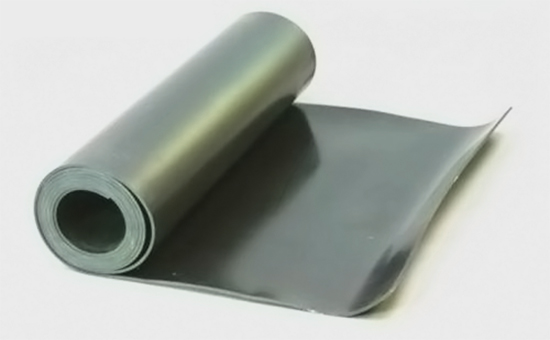

The low price of nitrile rubber reclaimed rubber and its large oil resistance coefficient make it an ideal raw material for the partial replacement of nitrile rubber to produce oil-resistant rubber products. How to better use nitrile reclaimed rubber to produce oil-resistant plastic sheet is a problem that every plastic sheet manufacturer is considering. So what's the skill to add nitrile reclaimed rubber to oil-resistant sheet rubber formula? How can we not only guarantee the oil resistance performance of nitrile rubber plate, but also reduce the cost of raw materials?

In theory, when the rubber sheet is produced, the quality of the product can be guaranteed when the proportion of reclaimed rubber is about 40%. Nitrile rubber sheet is no exception. However, in actual production, this ratio is not fixed, and the proportion of the nitrile reclaimed rubber blended in the rubber sheet must be determined according to the oil resistant rubber sheet formula, the quality of the nitrile regenerated rubber product, and the performance requirement of the nitrile rubber sheet.

Under the premise of guaranteeing the quality of nitrile reclaimed rubber products, if you want to produce high-quality oil-resistant rubber sheets, the blending ratio of nitrile reclaimed rubber is preferably around 30%. If you want to reduce more raw material costs, you need to adjust the nitrile rubber sheet formulation in a timely manner, increase the plasticizer, but the proportion of nitrile reclaimed rubber blending must not exceed 50%.

Some people think that the lower the price of nitrile reclaimed rubber used, the lower the raw material cost, but this is not the case. The lower the price of nitrile reclaimed rubber, the lower the product quality, the lower the rubber content and the oil resistance, and the method to improve the quality of the oil-resistant glueboard product is to use the original glue. The price of the nitrile rubber is higher than that of the nitrile rubber. Nitrile reclaimed rubber is high, so it is disadvantageous in terms of cost; relatively speaking, when using high-quality nitrile reclaimed rubber to produce oil-resistant rubber sheets, the proportion of nitrile reclaimed rubber can be increased, and the price of nitrile reclaimed rubber is higher. It is also high in nitrile rubber, which is more cost-effective, especially in the production of some high-standard oil-resistant rubber sheets.

In the actual production, both the nitrile rubber reclaimed rubber and the nitrile rubber in the oil resistant rubber board are replaced with nitrile reclaimed rubber instead of the production rubber board. The quality of the nitrile reclaimed rubber is particularly good. important. When selecting reclaimed rubber for oil-resistant rubber sheets, be sure to choose a high-quality, stable nitrile-containing reclaimed rubber, especially when producing environmentally-friendly oil-resistant rubber sheets indoors. Use environmentally-friendly nitrile-based reclaimed rubber, based on your own rubber sheet. The performance requirements, product grade amount mixed with nitrile reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits