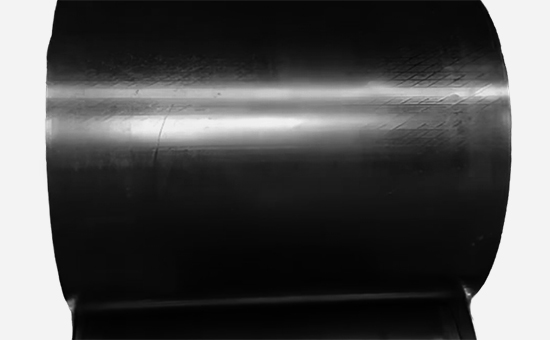

Oil-resistant rubber conveyor belt is mainly used for conveying oil substances or used in oil environments, and the conveyor belt covering rubber is in direct contact with oil substances, which plays the role of oil resistance, wear resistance and protection of the belt core, and rubber materials with good oil resistance need to be selected, such as nitrile rubber. When using nitrile rubber to produce oil-resistant conveyor belt covering rubber, an appropriate amount of nitrile reclaimed rubber, sub-brand nitrile butadiene rubber or styrene-butadiene rubber can effectively reduce the cost of raw materials on the premise of ensuring the oil resistance of the finished product.

1. Nitrile rubber/nitrile reclaimed rubber and use the production of oil-resistant rubber conveyor belt covering rubber vulcanization formula

70 parts of nitrile rubber, 30 parts of nitrile reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 2 parts of paraffin, 65 parts of semi-reinforcing furnace black, 10 parts of dioctyl phthalate DOP, 10 parts of coumaron resin, 8 parts of light calcium carbonate, 0.6 parts of accelerator TMTD, 1.5 parts of accelerator NS, 1.5 parts of sulfur; Total 204.6 copies.

2. Nitrile rubber/sub-brand nitrile butadiene rubber is used to produce oil-resistant rubber conveyor belt covering rubber vulcanization formula

60 parts of nitrile rubber, 40 parts of sub-brand nitrile rubber, 5 parts of zinc oxide, 0.5 parts of stearic acid, 40 parts of carbon black N880, 25 parts of silica, 40 parts of light calcium carbonate, 20 parts of dioctyl phthalate DOP, 20 parts of liquid coumarone, 1.2 parts of accelerator DM, 1.2 parts of accelerator CZ, 0.3 parts of accelerator TMTD, 2 parts of sulfur; Total 255.2 copies.

3. Nitrile rubber/styrene-butadiene rubber is used to produce oil-resistant rubber conveyor belt covering rubber vulcanization formula

75 parts of nitrile rubber, 25 parts of styrene-butadiene rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant D, 40 parts of carbon black N330, 16 parts of diethyloctyl sebacate DOS, 1.8 parts of accelerator DM, 0.7 parts of accelerator TMTD, 1.5 parts of sulfur; A total of 167 copies.

When the oil-resistant nitrile rubber conveyor belt uses low-cost rubber raw materials to reduce costs, the formula must be reasonably designed, carbon black, silica and other reinforcing agents can increase the wear resistance and tear resistance of the rubber compound, the plasticizer can improve the flexibility, E4LYY1028 and aging resistance of the rubber compound, and the design of the vulcanization system directly affects the physical and mechanical properties, wear resistance, and oil resistance of the conveyor belt covering rubber. In the future, Xiaobian will continue to share with you the formula design and production process points of the combination of nitrile rubber and nitrile reclaimed rubber to produce high-performance conveyor belts.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits