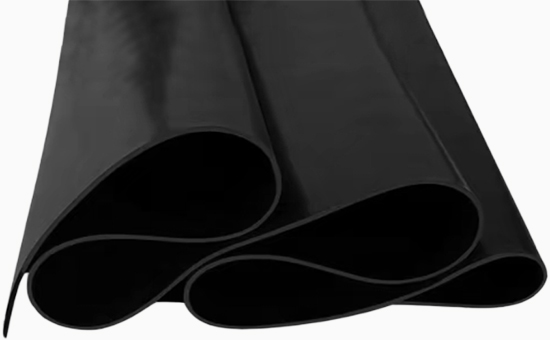

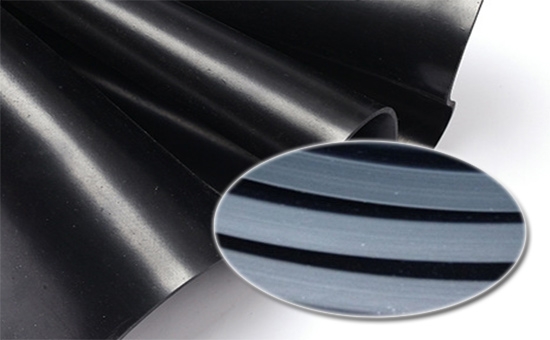

Oil-resistant rubber sheet is a sheet product with good oil resistance, a certain thickness and a large area processed from rubber as the main material, including pure rubber sheet or sandwich cloth, metal skeleton layer rubber sheet, etc. In actual production, oil-resistant rubber sheets are mostly processed from nitrile rubber; Proper use of reclaimed rubber can reduce the cost of raw materials. So which reclaimed rubber can be used in combination with nitrile rubber to produce oil-resistant rubber sheets? How much is appropriate? This article mainly shares several vulcanization formulas of nitrile rubber oil-resistant rubber sheets mixed with reclaimed rubber.

1. Nitrile rubber/nitrile reclaimed rubber is used to produce oil-resistant rubber sheet vulcanization formula

60 parts of nitrile rubber, 40 parts of nitrile reclaimed rubber, 4.5 parts of zinc oxide, 1.8 parts of stearic acid, 2 parts of antioxidant RD, 1.5 parts of paraffin, 35 parts of carbon black N330, 25 parts of carbon black N774, 35 parts of clay, 90 parts of stone powder, 18 parts of dibutyl phthalate, 0.9 parts of accelerator CZ, 0.45 parts of accelerator D, 1.35 parts of accelerator DM, 2 parts of sulfur; Total: 317.5 shares.

2. Nitrile rubber/tire reclaimed rubber is used to produce oil-resistant rubber sheet vulcanization formula

100 parts of nitrile rubber, 50 parts of tire reclaimed rubber, 5 parts of zinc oxide, 1 part of antioxidant D, 100 parts of carbon black N774, 35 parts of clay, 35 parts of dibutyl phthalate, 0.3 parts of accelerator D, 1 part of accelerator M, 2.5 parts of sulfur; Total: 329.8 copies.

3. Nitrile rubber/rubber shoe reclaimed rubber is used to produce oil-resistant rubber plate vulcanization formula

70 parts of nitrile rubber, 30 parts of PVC, 60 parts of rubber shoe reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant BLE, 100 parts of carbon black N774, 60 parts of light calcium carbonate, 25 parts of double fly powder, 15 parts of dibutyl phthalate, 5 parts of pine tar, 1.1 parts of accelerator CZ, 0.3 parts of accelerator TMTD, 2.1 parts of sulfur; Total: 376 copies.

Note: Nitrile rubber can be prepared with PVC in advance.

4. Nitrile rubber/nitrile reclaimed rubber/rubber shoe reclaimed rubber is used to produce oil-resistant rubber board vulcanization formula

30 parts of nitrile rubber, 15 parts of nitrile reclaimed rubber, 55 parts of rubber shoe reclaimed rubber, 2 parts of zinc oxide, 0.8 parts of stearic acid, 1 part of antioxidant RD, 0.6 parts of paraffin, 12 parts of carbon black N330, 12 parts of clay, 34 parts of light calcium carbonate, 40 parts of heavy calcium carbonate, 3.5 parts of dibutyl phthalate, 2.4 parts of pine tar, 1.2 parts of industrial fat, 0.75 parts of accelerator DM, 0.15 parts of accelerator TMTD, 0.6 parts of sulfur; Total: 211 copies.

The rubber sheet produced with nitrile rubber as the main raw material has excellent oil resistance, can work in oil oil medium for a long time, and has good sealing and anti-swelling; It is widely used in industrial and mining enterprises, transportation departments E4LYY12 and housing ground. The appropriate amount of reclaimed rubber in the oil-resistant rubber sheet can not only reduce the cost of raw materials and reduce the dependence on the original rubber; It can also improve the calendering performance of rubber compound, and improve the production efficiency and yield of oil-resistant rubber sheet.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits