Natural rubber can be used together with cis polybutadiene rubber, styrene butadiene rubber, recycled rubber or low-density polyethylene to produce ordinary industrial rubber sheet, and the raw rubber content can be controlled at 20% - 40%. The use of recycled rubber in the production of ordinary rubber sheet can effectively reduce the cost of raw rubber, improve the plasticity and fluidity of the compound; The combination of rubber and plastic can not only improve the performance of the rubber sheet, but also improve the service life of the rubber sheet and reduce the cost. When selecting plastic, try to choose the plastic whose solubility parameters are similar to those of rubber.

1. Natural rubber+cis polybutadiene rubber+polyethylene+recycled rubber to produce common rubber sheet formula

50 portions of natural rubber, 50 portions of cis polybutadiene rubber, 20 portions of low-density polyethylene, 180 portions of recycled rubber, 4 portions of zinc oxide, 1.5 portions of stearic acid, 2 portions of antioxidant A, 1 portion of paraffin, 40 portions of carbon black N330, 180 portions of stone powder, 4 portions of coumarone resin, 1.3 portions of accelerator DM, 1 portion of accelerator M, 0.2 portions of promoter TMTD, and 3 portions of sulfur; Total: 537 copies.

2. SBR+BR+PE+recycled rubber to produce common rubber sheet formula

50 SBR, 50 BR, 20 LDPE, 180 recycled rubber, 4 zinc oxide, 1.5 stearic acid, 2 antioxidant A, 1 paraffin, 40 carbon black N 330, 180 stone powder, 4 coumarone resin, 1.5 accelerator CZ, 0.4 accelerator TMTD, and 3.1 sulfur; Total: 537.5 copies.

In actual production, when using recycled rubber and low-density polyethylene to reduce the cost of ordinary rubber sheet, it is necessary to reasonably control the rubber content of the entire formula according to the use performance requirements. When raw rubber/reclaimed rubber/polyethylene is used to produce rubber sheets, the sulfur accelerator system is often selected. The amount of sulfur is controlled at 2-3 phr, and accelerator M, accelerator DM, accelerator D or accelerator TMTD are used for coordination. The rubber and plastic ordinary cloth is mostly reinforced with carbon black, and filled with calcium carbonate, clay and barite powder to reduce the cost; A softening system consisting of engine oil and coumarone resin is used to improve the processing properties of rubber and adjust the hardness of rubber.

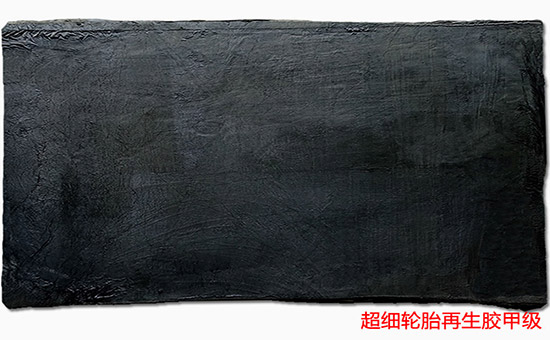

There are many recycled rubber products. Latex recycled rubber and tire recycled rubber are ideal raw materials for producing ordinary rubber sheets. In actual production, rubber product manufacturers can also completely use recycled rubber 2ELYY1228 to produce ordinary rubber sheets, reducing more raw material costs; When using recycled rubber to produce color rubber sheet, it is recommended to use white latex recycled rubber, which is easy to match colors and not easy to change colors. When producing ordinary rubber sheets with recycled rubber as the main raw material, the proper use of natural rubber, styrene butadiene rubber, polyethylene, etc. can further improve the performance of rubber sheets and prolong their service life.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits