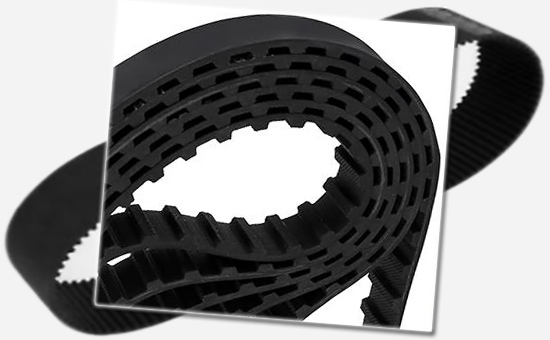

The rubber transmission belt is a new type of transmission belt with a toothed structure working surface processed from rubber. The ordinary flat transmission belt is mainly composed of cloth layer rubbing glue, sealing glue, butt glue and edge slurry glue. The natural rubber transmission belt is more common . The reasonable use of recycled rubber in the production process of natural rubber transmission belt can not only ensure the quality of the transmission belt, but also effectively reduce the cost of raw materials? So what problems should rubber manufacturers pay attention to when using recycled rubber to reduce the production cost of natural rubber transmission belts?

1. Different parts of natural rubber transmission belt have different rubber content

The performance requirements of different rubber layers of the rubber transmission belt are different. For example, the cloth layer eraser requires the rubber to have good fixed tensile stress, aging resistance, heat dissipation, etc. Generally, natural rubber and styrene-butadiene rubber are used together, and the rubber content is controlled at 50% Left and right; sealing glue and counterpart glue require fast curing and aging resistance, when the natural rubber is completely used, the glue content is controlled at about 40%; the performance requirements of the edge glue and sealing glue of the transmission belt are basically the same.

The performance requirements of different parts of the transmission belt are different, so there is a certain difference in the amount of reclaimed rubber mixed; under normal circumstances, the performance of the rubber layer of the natural rubber transmission belt 2LLYY65 directly affects the quality of the finished product, and the performance requirements are higher. The dosage is determined according to the effective rubber hydrocarbon content of the reclaimed rubber and the specific indicators of the cloth layer rubbing rubber; the amount of reclaimed rubber in the sealing rubber, the counter rubber and the side glue can be increased appropriately.

2. Selection skills of reclaimed rubber in natural rubber transmission belt

Natural rubber has good compatibility with latex reclaimed rubber and tire reclaimed rubber. Among them, latex reclaimed rubber with high rubber content can even completely replace natural rubber. When using recycled rubber to reduce the production cost of natural rubber transmission belts, rubber product manufacturers can choose latex recycled rubber or tire recycled rubber; when preparing brightly colored rubber transmission belt parts, you can use white latex recycled rubber, which is easier to match colors, such as sealing glue; if sealing The glue is red, and red latex reclaimed rubber can be used directly to reduce the cost of colorants. If you want to reduce more raw material costs, high-strength tire tread rubber is a good choice.

When using reclaimed rubber to reduce the production cost of natural rubber drive belts, rubber product manufacturers need to select the appropriate variety of reclaimed rubber according to actual needs, determine the amount of reclaimed rubber reasonably, appropriately adjust the production formula of natural rubber drive belts containing reclaimed rubber, and further optimize the performance of the drive belt. To reduce the cost of more raw materials, later editors will have the opportunity to discuss with you the formula design techniques of cost-effective natural rubber transmission belts containing reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits