Knowledge

-

When using EPDM rubber to produce rubber sealing strips, rubber product manufacturers can use EPDM reclaimed rubber in an appropriate amount according to actual needs to effectively reduce the cost of raw mater…

-

The vulcanized rubber powder retains the rubber elasticity and can be blended in different parts of the tire tread and sidewall to reduce tire manufacturing costs and improve the overall performance of the tire…

-

In the production of agricultural tires, styrene butadiene rubber and tire reclaimed rubber can be used together to prepare more cost-effective products. Among them, the physical properties of reclaimed tire ru…

-

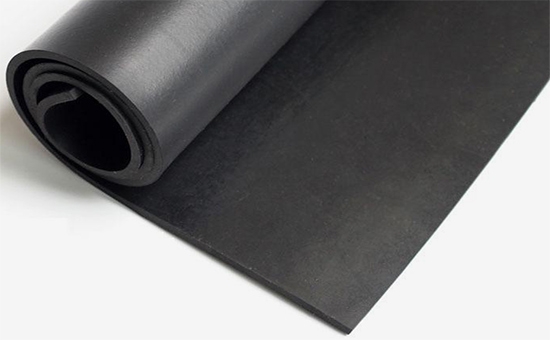

When using nitrile reclaimed rubber to reduce the raw material cost of oil-resistant rubber sheets, rubber product manufacturers can choose appropriate nitrile reclaimed rubber according to actual needs, and ap…

-

White carbon black is a commonly used white reinforcing filler in the production of rubber products, and its reinforcing effect is second only to carbon black. When silica is used to reinforce rubber products, …

-

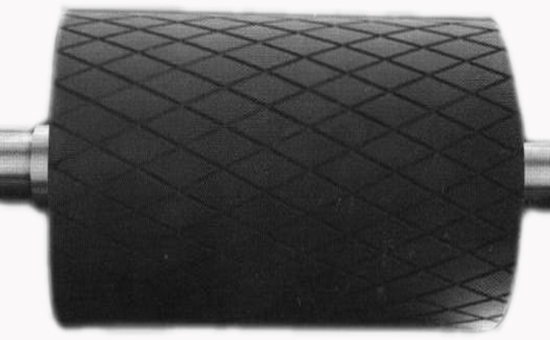

When using butyl reclaimed rubber to reduce the production cost of rubber rollers, rubber products manufacturers can choose to use butyl reclaimed rubber together with butyl virgin rubber, or use butyl reclaime…

-

When using latex reclaimed rubber to reduce the cost of covering rubber for steel wire rope conveyor belts, rubber products manufacturers need to select the appropriate variety of latex reclaimed rubber accordi…

-

The natural rubber mixing process can be carried out in the open mixer or internal mixer. Reasonable setting of the mixing process parameters can further improve the quality of the natural rubber finished produ…

-

EPDM reclaimed rubber retains the basic performance characteristics of EPDM virgin rubber, and can replace EPDM virgin rubber in a suitable ratio for use in the automotive industry, construction industry, elect…

-

TPU and rubber powder can be used together in a certain proportion to prepare a functional waterproof material with excellent waterproof and moisture permeability, which effectively reduces the cost of raw mate…

-

The combination of reclaimed tire rubber and a small amount of styrene butadiene rubber and butadiene rubber can prepare low-cost ordinary rubber sheets. Adjust the formula of ordinary rubber sheets mainly base…

-

When using nitrile reclaimed rubber instead of nitrile virgin rubber to produce oil-resistant rubber products, rubber product manufacturers need to appropriately adjust the product formula according to actual n…

-

When using rubber fillers to reduce the raw material cost of rubber products, rubber product manufacturers need to comprehensively consider the physical properties of rubber products and production costs, and r…

-

When using butyl reclaimed rubber to reduce the raw material cost of acid and alkali resistant hoses, rubber product manufacturers need to reasonably control the amount of butyl reclaimed rubber, appropriately …

-

When using latex reclaimed rubber to produce rubber products, proper adjustment of the scorch time can further improve the processing safety and yield of reclaimed rubber products. Rubber product manufacturers …

-

When using natural rubber to produce electrical insulating rubber products, rubber products manufacturers can properly adjust the softening system and anti-aging system compounding agents to further improve the…

-

When using natural rubber to produce insulation products, rubber product manufacturers need to design formulas reasonably and pay attention to the influence of various compounding agents on the insulation perfo…

-

When using tire rubber powder to reduce the cost of raw materials for automobile cushion belts, rubber product manufacturers can select the appropriate mesh size of tire rubber powder according to actual needs,…

-

Tire reclaimed rubber can be used together with a small amount of butadiene rubber and styrene butadiene rubber to prepare ordinary shock-absorbing tires. Appropriate adjustment of the types of rubber raw mater…

-

When using nitrile reclaimed rubber to produce skeleton oil seals, rubber product manufacturers need to focus on oil resistance, tensile strength, hardness, wear resistance, permanent deformation, temperature r…