The volume resistivity of nitrile rubber reaches 1010-1011Ω·cm. It is often used in combination with reclaimed tread rubber to produce various conductive materials such as conductive rubber sheets. Its volume resistivity is compared with pure nitrile rubber. It can be reduced by 7-9 orders of magnitude, which can not only ensure the good performance of conductive materials, but also effectively reduce the cost of raw materials. So why can nitrile rubber/tread reclaimed rubber produce conductive materials? What are the factors related to the volume resistivity of nitrile rubber/reclaimed rubber?

1. The cyano group in nitrile rubber affects the dielectric properties of the rubber compound

The nitrile rubber formed by polymerization of butadiene and acrylonitrile contains cyano groups in the molecular chain, which gives the rubber excellent oil resistance. However, the cyano group is easily polarized by the electric field, which causes the dielectric properties of the nitrile rubber to decrease, so the nitrile rubber is a semiconducting rubber. Using nitrile rubber as the main material to prepare conductive rubber can effectively prevent the problem of conductive products from changing due to oil swelling in an oil medium.

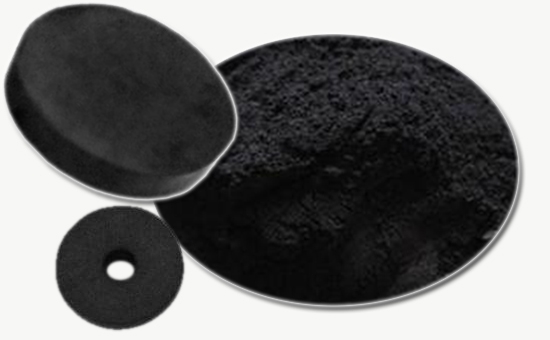

2. The amount of acetylene carbon black affects the volume resistivity of nitrile rubber/reclaimed rubber combined rubber

Acetylene carbon black has the characteristics of developed structure, large void volume, and strong liquid absorption ability. It is an indispensable matrix material in nitrile rubber conductive materials. When using nitrile rubber/reclaimed rubber to produce conductive rubber products, the amount of acetylene carbon black in the formula directly affects the volume resistivity of the rubber compound. Under normal circumstances, the volume resistivity of the nitrile rubber/reclaimed rubber compound will continue to decrease with the increase in the amount of acetylene carbon black, and the conductivity of the compound will be better.

3. The amount of reclaimed rubber affects the volume resistivity of nitrile rubber/reclaimed rubber combined rubber

When nitrile rubber and tread reclaimed rubber are used to prepare cost-effective conductive rubber products, the volume resistivity of the combined rubber compound is related to the addition ratio of the tread reclaimed rubber. Generally, the greater the proportion of reclaimed rubber added, the smaller the volume resistivity of the nitrile rubber/tread reclaimed rubber compound.

In actual production, the increase in the amount of tread reclaimed rubber will reduce the mechanical strength of the combined rubber. Therefore, a small amount of tread reclaimed rubber can be combined with nitrile rubber to prepare conductive rubber products with higher mechanical performance requirements of 2LLYY97, and a small amount of nitrile rubber can be combined with tread reclaimed rubber to prepare conductive rubber products with lower mechanical performance requirements.

4. Other factors affecting the volume resistivity of nitrile rubber/reclaimed rubber combined

In actual production, the vulcanization system, plasticization system, mixing process, vulcanization process conditions and other factors of the nitrile rubber/reclaimed rubber combined rubber will affect the volume resistivity of the rubber compound. Choosing a sulfur vulcanization system for high temperature vulcanization is beneficial to reduce the volume resistivity of the combined rubber; too long mixing time will cause the volume resistivity of the nitrile rubber/reclaimed rubber to increase and the conductivity to decrease; when using DOP for plasticization, the addition of DOP It will cause the conductivity and mechanical properties of the combined rubber to decrease.

Reasonable use of tread reclaimed rubber in nitrile rubber can prepare more cost-effective conductive materials. I have the opportunity to continue discussing with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits