The main component of latex recycled rubber is rubber hydrocarbon, which has the characteristics of high mechanical strength and good elasticity, and is widely used in daily production, medical and health, industry and agriculture and other fields. Rubber is a bad conductor of electricity. Latex reclaimed rubber has good electrical insulation and can be used to produce various types of rubber cable sheaths, insulating rubber sheets, insulating rubber pads and other products. At the same time, latex recycled rubber can also be used in the production of conductive rubber products, so what are the factors that affect the electrical properties of latex recycled rubber? How to meet the special needs of different rubber products?

1. The effect of rubber molecular polarity and saturation on electrical properties

In actual production, the electrical insulation of rubber is related to the molecular structure of the rubber, which mainly depends on the polarity and saturation of the molecules. In general, non-polar rubbers have good electrical insulation properties, such as latex regenerated rubber, cis-butadiene rubber, styrene-butadiene rubber, butyl rubber, ethylene-propylene rubber, etc. Polar rubber is not suitable for the production of electrical insulating rubber products, especially high-voltage electrical insulating rubber products. Common polar rubbers include chloroprene rubber, chlorosulfonated polyethylene rubber, and chlorobutyl rubber.

In actual production, ethylene-propylene rubber and butyl rubber can be used to produce high-voltage electrical insulating rubber products, while natural rubber, styrene-butadiene rubber, cis-butadiene rubber and their concomitant rubbers are mostly used to produce medium and low voltage rubber products; non-polar rubber can be used for Outdoor electrical insulating rubber products with low degree of insulation; nitrile rubber and nitrile rubber/polyvinyl chloride blends can be used to produce heat-resistant, oil-resistant and flame-retardant electrical insulating rubbers.

2. Vulcanization system affects the electrical properties of latex reclaimed rubber

Sulfur is the most commonly used vulcanizing agent for latex recycled rubber products. In the vulcanizate based on latex reclaimed rubber, as the amount of sulfur increases, the initial electrical conductivity of latex reclaimed rubber decreases; when the amount of sulfur increases to about 18 parts, the electrical conductivity reaches a maximum value; if the amount of sulfur continues to increase, the electrical conductivity will continue to increase. decline. The dielectric constant and dielectric loss of the rubber compound increase with the increase of the amount of sulfur; when the amount of sulfur reaches 10-14 parts, the maximum value appears; if the amount exceeds this amount, the dielectric constant and dielectric loss decrease, and the electrical insulation performance is improved. get better.

In actual production, when the amount of sulfur is large, the electrical insulation performance of the latex reclaimed rubber vulcanizate is better, but the heat resistance performance is obviously reduced. Therefore, when the latex recycled rubber is used to prepare soft insulating rubber, it is recommended to use a low-sulfur or no-sulfur vulcanization system.

3. The filler system affects the electrical properties of latex reclaimed rubber

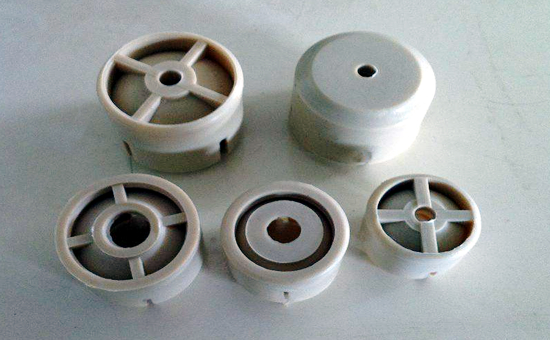

The amount of fillers in rubber products is very large. The type and amount of fillers are important factors that affect the electrical insulation and conductivity of latex recycled rubber products. In general, flaky and flat particle fillers can form a barrier against electrical breakdown, which is beneficial to electrical insulation; non-black inorganic fillers such as calcium carbonate, mica powder, talc powder, silica, aluminum hydroxide, magnesium carbonate, etc. And carbon black with large particles and low structure is mostly used in the production of electrical insulating rubber products.

When the latex reclaimed rubber is used to produce medium and low voltage electrical insulating rubber products, the commonly used fillers are calcium carbonate, talc and ordinary clay. During use, fillers with strong water absorption and moisture will reduce the electrical insulation performance of the vulcanizate. Therefore, special attention should be paid to the water absorption and moisture content of the fillers when selecting fillers for latex reclaimed rubber. In order to reduce the surface hydrophilicity of rubber fillers and improve the affinity of fillers and latex reclaimed rubber, fatty acid or silane coupling agent can be used to modify the surface of inorganic fillers such as clay and silica.

4. The softening system affects the electrical properties of latex reclaimed rubber

The softening system will affect the electrical properties of rubber to a certain extent, especially high-voltage electrical insulation rubber products. When producing medium and low voltage electrical insulation rubber products with latex reclaimed rubber as the main raw material, it is recommended to use paraffin hydrocarbon oil with the dosage controlled at about 5-10 parts. It should be noted that the amount of paraffin oil will spray out of the surface of the product, which will affect the adhesion effect. Especially in the bonding molding, it is recommended to use paraffin oil and gummalone resin together to further increase the self-adhesion of latex reclaimed adhesive.

5. The anti-aging system affects the electrical properties of latex reclaimed rubber

In actual production, the softening system will also affect the electrical properties of latex reclaimed rubber vulcanizate. It is recommended to use amine or p-phenylenediamine antioxidant, and anti ozone agent can be used if necessary. When choosing antioxidants, attention should be paid to the water absorption and purity of antioxidant; In addition, amine antioxidant will also interfere with peroxide vulcanization, so it is not recommended to use amine antioxidant for latex reclaimed rubber vulcanized by peroxide.

There are many factors that affect the electrical properties of latex reclaimed rubber. In the later stage, Xiaobian will continue to discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits