Knowledge

-

The use of EPDM recycled rubber to produce EPDM rubber pad is a low-cost raw material choice to ensure quality, by reducing the cost of EPDM rubber pad and reasonable dosage of additives, the use of EPDM recycl…

-

Recycled nitrile rubber is a new material with high quality and low price, which has the characteristics of reducing specific gravity and improving oil resistance. Oil-resistant rubber liner mixed with recycled…

-

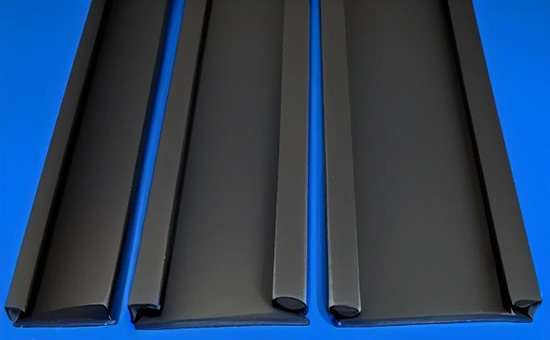

The low-cost formula with EPDM recycled rubber powder mixed with cable jacketing has a lighter specific gravity, reducing product weight and increasing installation flexibility. Through reasonable vulcanization…

-

The new raw material manufacturing technology of butyl sealing rubber stopper can reduce the specific gravity and raw material cost by adding butyl recycled rubber, which not only has the characteristics of env…

-

The application of high-strength tire recycled rubber in the manufacture of shock-isolation rubber bearings not only reduces the specific gravity and raw material cost, but also realizes the characteristics of …

-

The use of rubber reinforcing agents in rubber products can not only reduce the specific gravity and raw material cost to achieve energy saving and consumption reduction, but also improve the tensile strength o…

-

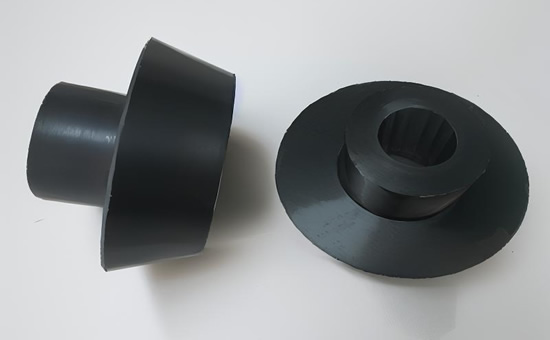

EPDM recycled rubber has the characteristics of cost reduction, performance improvement, energy saving and consumption reduction and green environmental protection in the production of insulated shock absorbing…

-

The oil-resistant and wear-resistant rubber sheet produced by nitrile reclaimed rubber has excellent oil, wear, weather resistance and other properties, and is suitable for various industrial fields that need t…

-

The mixing of latex recycled rubber powder in rubber products has important advantages such as reducing the proportion and cost, energy saving and consumption reduction, and green environmental protection. By i…

-

Butyl reclaimed rubber has similar properties to butyl rubber and is more affordable, through the right vulcanization formula and fine rubber mixing processing can produce high-quality building acoustic mats. T…

-

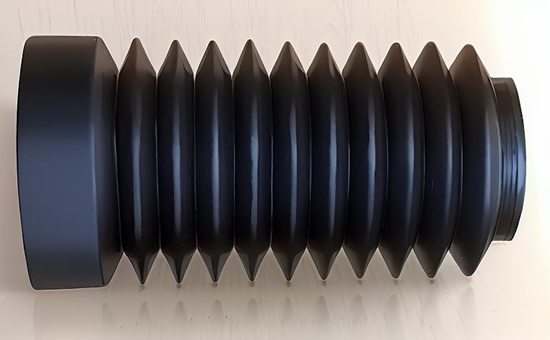

The use of black latex recycled rubber instead of natural rubber to produce electric vehicle dust jackets has outstanding advantages such as cost performance, environmental protection and sustainability. Throug…

-

Tread regeneration rubber production, drum adhesion and vulcanization formulation design of ceramic sheets is a complex and critical process. By rationally selecting tread regeneration rubber, optimizing vulcan…

-

Because recycled rubber will release some special taste during processing and use, this leaves people with the impression that the quality of recycled rubber is relatively poor or the recycled rubber is not goo…

-

By optimizing the vulcanization formula and compounding process of EPDM reclaimed rubber to produce low-hardness sealing shock absorbing gasket, it is possible to prepare a sealing shock absorbing gasket with e…

-

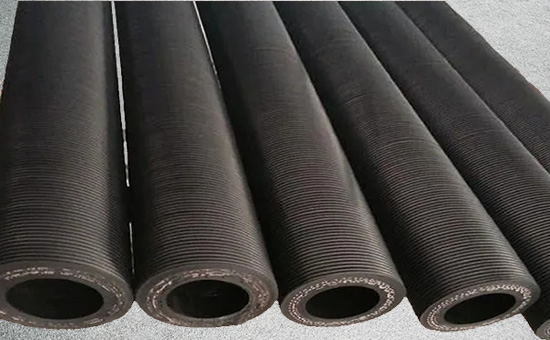

Nitrile regeneration rubber production oil-resistant and wear-resistant mud pipe inner wall glue vulcanization formula is a complex process, need to choose the right nitrile regeneration rubber for scientific p…

-

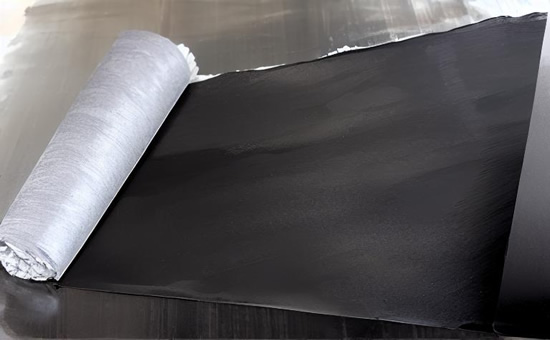

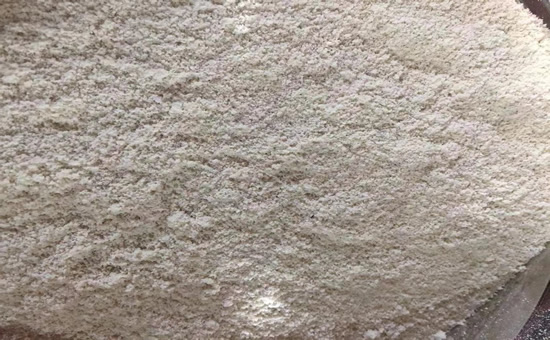

Latex reclaimed rubber powder for waterproof mortar has the characteristics of low cost, energy saving and environmental protection, good bonding, improving crack resistance and waterproof performance, anti-agi…

-

In addition to latex reclaimed rubber, manufacturers of rubber seals may also use cis-butadiene rubber, neoprene rubber, styrene-butadiene rubber, nitrile rubber, EPDM rubber and other common recycled rubber, t…

-

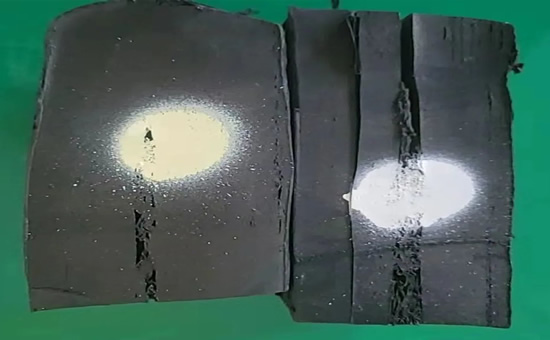

The white paint spray test can quickly and easily determine whether the tire reclaimed rubber has migrated, and if higher accuracy is required, a heat aging test is required. Other methods include thermogravime…

-

EPDM recycled rubber as a material for the production of special-shaped valve rubber fittings has the advantages of high temperature resistance, corrosion resistance, wear resistance, etc., and its performance …

-

The surface of recycled rubber products is smooth and oily and not white, and it is necessary to pay attention to the vulcanization formula combination and the vulcanization process of mixed rubber to avoid exc…