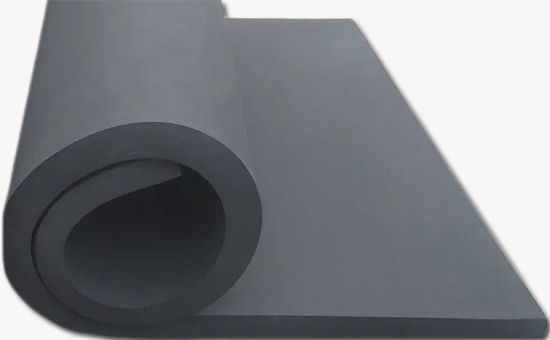

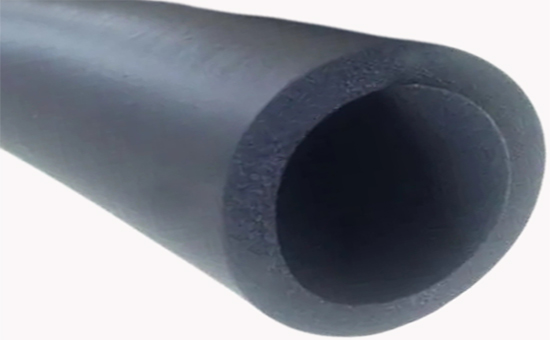

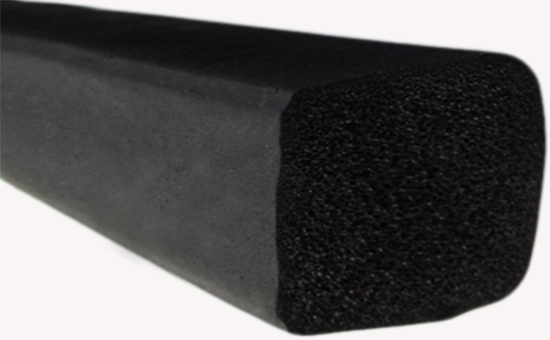

The latex reclaimed rubber has high effective rubber hydrocarbon content, has the basic performance characteristics of natural rubber, high strength, good elasticity, small specific gravity, high elongation at break, and is simple in molding process and not prone to vulcanization reversion compared with natural rubber. Therefore, natural latex renewable rubber can directly replace natural rubber or be used with natural rubber, styrene-butadiene rubber, cis-polybutadiene rubber, isoprene rubber, etc. to produce various sponge rubber products, such as sponge rubber plate, sponge rubber sole, sponge rubber strip, etc., effectively reducing the cost of raw materials.

In order to ensure the processing performance and service performance of sponge rubber, the following requirements are put forward for the latex reclaimed rubber used when preparing sponge rubber products.

1. Properly control the plasticity of latex recycled rubber

The plasticity of the rubber compound directly affects the size and density of the porous rubber eyelet. It is recommended that the plasticity of the rubber compound be controlled among 0.5-0.6 (Vickers) when preparing the porous rubber with latex reclaimed rubber. In actual production, the greater the plasticity of the latex reclaimed rubber 2SLYY22, the greater the flexibility of the rubber material, the easier the pores, the larger the pores and the smaller the density; The smaller the plasticity is, the opposite is true; Excessive or insufficient molding can also affect hair pores.

2. It is necessary to control the pore forming speed and curing speed for the preparation of foam rubber from latex reclaimed rubber

When using latex reclaimed rubber to produce sponge rubber products such as sponge rubber soles, sponge rubber plates, sponge sealing strips, etc., the pore-forming speed and curing speed of sponge rubber should be consistent. In the process of pore formation of latex regenerated rubber, the rubber has been initially vulcanized at the beginning of pore formation, which can give certain strength to the hole wall, so as to prevent the gas from breaking through the hole wall to form an opening; If the pore growth rate is slower than the curing rate, the pore size is small and the surface adhesive layer is thick; The curing speed is slower than the hair hole speed, the hair hole is large, the hole size is uneven, and the skin is thin.

3. When using latex reclaimed rubber to prepare sponge rubber, the internal pressure of the rubber material during the hole formation should be greater than the external pressure to avoid the hole formation.

4. The rubber compound is required to have good thermal conductivity to ensure that the internal and external pores are uniform and the curing degree is consistent.

5. Pay attention to the color of latex regeneration adhesive

When preparing foam rubber with latex reclaimed rubber, it is recommended to use latex reclaimed rubber with the color similar to that of foam rubber products. For example, white and light-colored sponge rubber soles can use white latex reclaimed rubber, which is easy to match color and not easy to change color; Black foam rubber board uses black latex recycled rubber, which has lower cost; There are also red latex recycled rubber, green natural recycled rubber and other color latex recycled rubber on the market, so the color recycled rubber of corresponding color can also be selected for the production of color sponge rubber products.

When using latex reclaimed rubber to reduce the production cost of sponge rubber products, it is necessary to select the appropriate latex reclaimed rubber, strictly control the plasticity of the recycled rubber material, and reasonably design the formula of rubber products, especially the vulcanization system and foam system. Later, the editor will continue to share with you the key points of the production process of latex reclaimed rubber to produce sponge rubber products such as sponge rubber soles, sponge rubber plates, sponge rubber tubes, and sponge tapes Formula design skills and practical formula.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits