The railway sleeper is a kind of important accessory in the railway. It has three main functions: supporting the rail, maintaining the position of the rail, transferring the huge pressure transmitted by the rail to the track bed, and being flexible, elastic, cushioning, and back. Elasticity requirements are particularly high, traditional wooden sleepers and reinforced concrete sleepers. At present, with the continuous advancement of various technologies, waste tire reclaimed rubber powder is used as a new type of raw material in the processing of sleepers. How to apply tire rubber powder in railway sleepers?

1. Domestic waste rubber waste plastic composite railway sleeper technology

This technology is proposed in the “Eleventh Five-Year Plan” of China Railways, which was issued by the National Development and Reform Commission, the Ministry of Science and Technology, and the State Environmental Protection Administration, “Resource Utilization and Environmental Protection Technology Encouraged by the State”: The rubber powder and the waste plastic are blended to obtain a thermoplastic elastomer as a sleeper shell, and the cement sleeper core is strengthened, and a special composite railway sleeper which has the advantages of both the wooden railway sleeper and the concrete railway sleeper and overcomes the inherent shortcomings is obtained through special processing.

Supplementary note: The wooden sleeper is a sleeper made of tough and elastic wood. It has good elasticity, easy processing and convenient use, but its elasticity, strength and durability are not uniform enough, its service life is short, and it is easy to minor repair, wear and crack. The domestic wood resources are scarce, and most of them have been replaced by concrete sleepers; concrete sleepers have long service life and good track stability, which can meet the requirements of high speed and large volume, but they have large rigidity and poor elasticity, which leads to increased pressure and vibration acceleration of the track bed. Large, exacerbating the chalking of the ballast, causing the sinking of the track to increase, adversely affecting the part of the train. Therefore, it is imperative to develop a new type of railway sleepers. This technology can not only improve the comprehensive performance of railway sleepers, but also solve the environmental pollution problems caused by a large number of waste tires and waste plastics, and achieve optimal resource allocation.

2, tire rubber powder + sand stone + cement

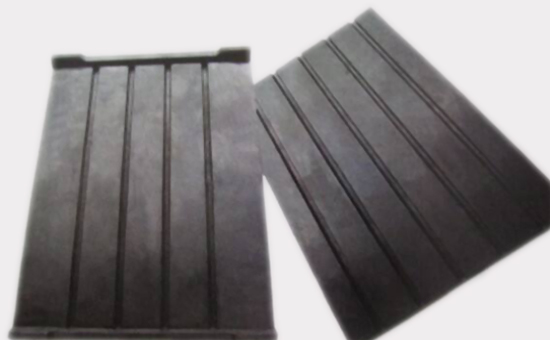

The technology was invented by South Korea. It mixes used tire rubber powder, sand and water, and uses specific molds to make light, impact-resistant and corrosion-resistant railway sleepers. It can reduce the noise during train travel. Vibration, improve the life of the pavement, reduce maintenance, increase the safety of the crossing, and greatly reduce the impact of heavy-duty vehicles on the line.

3, composite railway elastic sleepers: waste plastic + waste paint + tire rubber powder plastic blending

The technology is to put waste plastics, waste paint and waste tire rubber powder together by plasticizing and blending through a special process to obtain a property close to wood, elasticity, strength, corrosion resistance, and processing performance superior to wood regeneration. Rubber and plastic composites.

4. A plastic sleeper craft ratio with tire rubber powder added

Various waste wire sheaths including waste PVC sheathed wire (PVC), fluoroplastic waste wire sheath (PTFE), polyfluoroethylene propylene waste wire sheath (FEP), polypropylene waste wire sheath (PP) and used tires are all Solid waste, the use of these waste rubber products in the production of railway sleepers can reduce production costs, can also alleviate white pollution and black pollution, and improve the elasticity, cushioning, insulation, cold resistance of the sleepers, etc. Plastic sleepers have a long service life and will not break under the low temperature of minus 60 degrees Celsius. The specific waste resources are as follows: PVC, 40-60 parts; waste tire rubber powder, 18-25 parts; PTFE, 1-5 parts; FEP, 1-5 parts; PP, 1-15 parts.

At present, the application technology of waste tire reclaimed rubber powder in railway sleepers is constantly improving. Various new railway sleepers with tire rubber powder are used in elasticity, impact resistance, corrosion resistance, shock absorption, sound absorption and service life. At the same time, the use of waste tire rubber powder in the production of railway sleepers can turn waste into treasure, realize the recycling of waste rubber resources, and can also process a large number of used tires and alleviate various solid waste rubber belts. The environmental pollution that comes is a new raw material for railway sleepers that is worth exploring and researching.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits