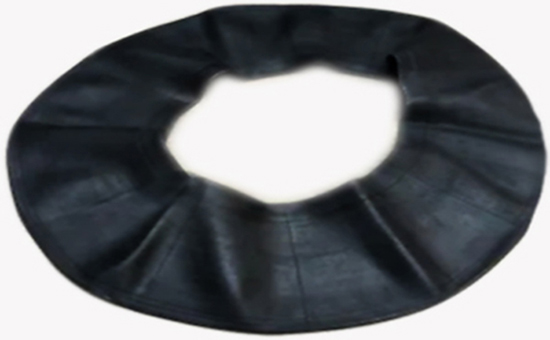

Butyl reclaimed rubber has excellent air tightness and water tightness, and can be used alone or combined with butyl rubber to produce automobile, motorcycle, bicycle inner tube products, effectively reducing the cost of rubber inner tube raw materials. When butyl rubber, butyl reclaimed rubber or butyl rubber/reclaimed rubber are used together to prepare butyl rubber inner tubes, the extrusion process is very important, and this article mainly shares with you the precautions for the extrusion process of butyl rubber inner tubes.

1. Pay attention to the hot mixing temperature and roll distance

When using butyl rubber, butyl reclaimed rubber or butyl rubber/reclaimed rubber and rubber to prepare rubber inner tubes, it is recommended to use low-temperature hot mixing for butyl rubber, and fully refine the small roller spacing under cold roll conditions; The temperature of the front roll should be controlled at 45-55 °C, and the temperature of the rear roll should be among 50-60 °C, which will help the rubber to form a good roll state on the front roll and avoid excessive molecular chain relaxation. Better maintain the elastic state of the compound.

2. Pay attention to the operating temperature of the straining process

Fluid filtration is a critical step in ensuring the quality of butyl rubber inner tubes. In actual production, the temperature of the rubber strip should be controlled below 80°C, the body temperature should be 50±5°C, and the head temperature should be 70±5°C. The gel temperature after straining should not exceed 135°C. Use one layer of 28 mesh and one layer of 40 mesh filters to ensure the uniformity and purity of the butyl compound.

3. Pay attention to the timing of adding sulfur and the process operation after adding sulfur

Butyl rubber, butyl reclaimed rubber, butyl rubber/reclaimed rubber combined rubber use sulfur-accelerator system in the production of rubber inner tubes, and the sulfur adding process has a significant impact on product quality. There are two kinds of adding time for sulfur, adding sulfur after the filter gel and adding sulfur first and then filtering the gel.

(1) Add sulfur after strainer: It is recommended to add sulfur and superaccelerator such as TMTD under the cold roller; First of all, the rubber material dissipates heat, then extracts the remaining glue, adds sulfur Yellow River super accelerator, eats it clean, goes through 3-4 times of thin passing, 2-3 triangular bags, and then slams the film, and the whole operation process takes about 10 minutes; The compound is parked to be extruded.

(2) Add sulfur first and then filter gel: butyl rubber has poor miscibility and dispersibility, and sulfur is unevenly dispersed, which is prone to sulfur spots, resulting in quality problems such as delamination and sand hole after extrusion; Compared with butyl rubber, butyl reclaimed rubber E4LYY129 has better compatibility and dispersion. Sulfur is added first and then the filter can better ensure the quality of semi-finished products; The temperature of each section is 5-10 °C lower than that of the extrusion process of first straining and then adding sulfur, and the temperature of the glue after straining should not exceed 105-125 °C to avoid scorching; At this time, there is no need to park after straining, and it can be directly refined for the extruder to extrude.

When producing butyl rubber inner tubes, butyl rubber needs to be refined at low temperature before extrusion, at this time, it is necessary to pay attention to the screw speed, and the rubber cartridge must be parked for 4 hours after extrusion before use. When using butyl rubber and butyl reclaimed rubber as the main raw materials to produce rubber inner tubes, rubber product manufacturers also need to reasonably determine the mixing ratio of butyl reclaimed rubber, appropriately adjust the production formula and various production processes, and then continue to discuss with you the skills and production process points of butyl rubber inner tubes.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits