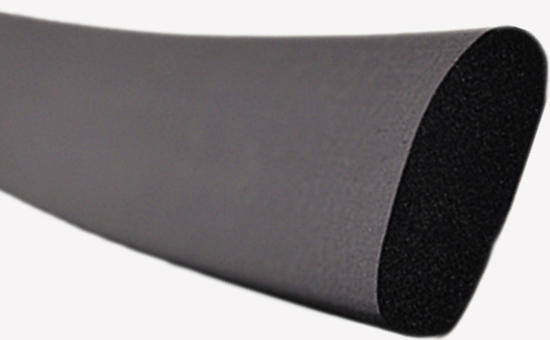

Oil-resistant sponge rubber sealing strips can maintain stable performance in the environment of contact with oil media, and are widely used in automobiles, hydraulic equipment, air conditioning systems and other occasions. Nitrile rubber has good oil resistance, wear resistance and aging resistance, and is an ideal raw material for the production of oil-resistant sponge sealing strips; Nitrile reclaimed rubber retains the basic performance characteristics of nitrile rubber, and can replace part of nitrile rubber to produce oil-resistant rubber sealing strips, effectively reducing raw material costs and production energy consumption.

1. Nitrile rubber/nitrile reclaimed rubber and closed-cell sponge sealing strip are produced

60 parts of nitrile rubber, 40 parts of nitrile reclaimed rubber, 4.5 parts of zinc oxide, 1.8 parts of stearic acid, 1 part of antioxidant RD, 22 parts of dibutyl phthalate, 30 parts of titanium dioxide, 0.8 parts of accelerator CZ, 0.4 parts of accelerator D, 1.5 parts of sulfur, 5 parts of foaming agent AC, 5 parts of foaming agent OBSH, total: 207 parts.

2. Nitrile rubber/nitrile reclaimed rubber and use to produce open-cell sponge sealing strips

60 parts of nitrile rubber, 40 parts of nitrile reclaimed rubber, 4.5 parts of zinc oxide, 1.8 parts of stearic acid, 15035 parts of carbon black, 11 parts of dibutyl phthalate, 13.5 parts of liquid nitrile rubber, 4.5 parts of titanium dioxide, 1.2 parts of accelerator DM, 0.2 parts of accelerator TMTM, 2 parts of sulfur, 8 parts of foaming agent H, 4 parts of foaming agent TSH, total: 185.7 parts.

3. Nitrile rubber/nitrile reclaimed rubber combined with the production of oil-resistant sponge sealing strip formula design points

(1) Foaming system and vulcanization system

When using nitrile reclaimed rubber instead of a certain proportion of nitrile primary rubber to produce oil-resistant sponge rubber sealing strips, it is necessary to focus on the balance of caving speed and vulcanization speed generated by the foaming agent and vulcanizing agent after use, so as to ensure that the density, temperature and pores of the finished sealing strip are uniform.

The decomposition rate of foaming agent H is fast, and the amount of gas (nitrogen, ammonia) produced is large, if the melt strength of the rubber compound is not enough, it is easy to crack the pore wall of the sponge rubber and form an open pore structure, and when the internal pressure is reduced, the shrinkage is also larger. Foaming agent AC is non-toxic, tasteless, discolored, non-polluting, is a stable foaming agent, the decomposition of nitrogen, carbon monoxide, ammonia and carbon dioxide permeability is smaller than that of foaming agent H, easy to form closed-cell structure sponge, its shrinkage is also smaller than H.

In actual production, open-cell sponge rubber usually chooses a foaming agent with large gas generation and large gas permeability; The rate of vulcanization and foaming needs to be controlled to ensure that the gas E4LYY43 can escape smoothly and form a uniform open cell structure. Closed-cell sponge rubber selects a foaming agent with small gas generation and low gas permeability to form a closed-cell structure; It is necessary to control the decomposition rate of the blowing agent and the degree of cross-linking of the rubber to ensure the independence and stability of the bubble cells.

(2) Reinforcement system and softening system

When nitrile rubber/reclaimed rubber is used together to produce oil-resistant sponge rubber sealing strips, the commonly used reinforcing agent fillers are carbon black (which significantly improves the tensile strength, abrasion resistance and tear resistance of rubber), silica (silica treated with silane coupling agent can also provide good reinforcing effect and is suitable for light-colored oil-resistant sponge rubber sealing strips), calcium carbonate (improve reinforcing properties and reduce costs) and clay (can improve the hardness and heat resistance of rubber).

The main function of the softening plasticization system is to improve the processability and flexibility of rubber. For the preparation of oil-resistant sponge sealing strips using nitrile rubber and nitrile recycled rubber, commonly used softening plasticizers include petroleum-based plasticizers such as DOP (dioctyl phthalate) and DOA (diisodecyl phthalate), which significantly improve the flexibility and processability of rubber. Ester plasticizer, good compatibility, obvious growth effect; Polyester plasticizers such as ADP (dioctyl adipate) have excellent heat and oil resistance.

When using nitrile rubber and nitrile reclaimed rubber as the main raw materials to process oil-resistant sponge sealing strips, the design of the reinforcing filling system and the softening plasticization system needs to comprehensively consider the performance requirements, processing technology and cost of the product. For example, for sealing strips with higher oil resistance requirements, it may be necessary to choose more oil-resistant plasticizers; For seals that need to improve wear resistance, it may be necessary to increase the amount of carbon black; Through formula optimization, we can produce more low-cost, high-performance nitrile oil-resistant sponge seals that meet the demand.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits