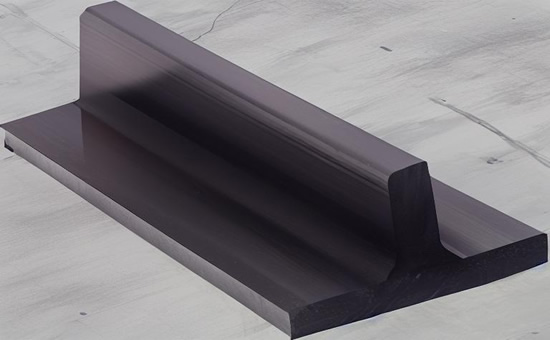

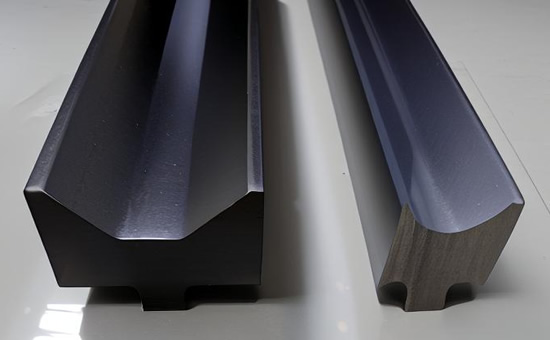

T-type rubber sealing strips are mainly used in industrial, automotive and other fields to provide good sealing performance. When selecting a compound for a T-shaped rubber seal, consider its oil resistance, temperature resistance, chemical resistance, durability and processability. Reclaimed rubber is the main raw material for reducing costs in the rubber products industry, and when reclaimed rubber with oil resistance is used in T-shaped rubber sealing strips, it can save the cost of rubber and ensure the good oil resistance of T-shaped rubber sealing strips.

Nitrile reclaimed rubber retains the basic performance characteristics of nitrile original rubber, has good oil resistance and wear resistance, can be used alone or combined with nitrile original rubber to produce oil-resistant T-type rubber sealing strip, need to consider its oil resistance, temperature resistance, chemical resistance, durability and processing performance, select the appropriate nitrile reclaimed rubber, and reasonably determine the vulcanization formula of nitrile reclaimed rubber.

1. Design of vulcanization system for the production of T-type sealing strip formula for oil-resistant reclaimed rubber

When using nitrile reclaimed rubber to produce oil-resistant T-type rubber sealing strips, it is recommended to use sulfur-accelerator system, use two or three accelerators such as accelerator M, accelerator D, accelerator DM, accelerator TMTD and other accelerators to promote vulcanization, and use zinc oxide and stearic acid as vulcanization active agents to improve the cross-linking density and improve the oil resistance and heat resistance of vulcanized rubber.

2. Oil-resistant reclaimed rubber production T-type sealing strip formula reinforcement filling system design

For oil-resistant rubber products, generally reducing the volume fraction of rubber in the rubber compound can improve the oil resistance, and the oil resistance of the oil-resistant reclaimed rubber vulcanized rubber can be further improved by appropriately increasing the amount of filler. In general, the higher the activity of the filler (carbon black, silica) and the rubber, the stronger the binding force, and the smaller the volume swelling of the vulcanized gum. Therefore, the production of T-type sealing strips by oil-resistant nitrile reclaimed rubber can not only use carbon black or silica to improve the mechanical properties, but also improve the oil resistance of the rubber compound.

3. Design of oil-resistant reclaimed rubber production T-type sealing strip formula softening and plasticizing system

When designing the oil-resistant reclaimed rubber formulation, the extraction of the compounding agent needs to be considered in the design of the softening plasticizing system. It is recommended to use softening plasticizers with large molecular weight, low volatility and not easy to be extracted by oil in the formula of oil-resistant T-type reclaimed rubber sealing strips, and it is best to use low-molecular polymers, such as low-molecular weight polyethylene, oxidized polyethylene, coumeron, polyester plasticizers and liquid rubber. Softening plasticizers or plasticizers with high polarity and high molecular weight are good for oil resistance, while esters are easy to be pumped out of fuel.

4. Design of anti-aging system for the production of oil-resistant reclaimed rubber T-type sealing strip formula

The choice of antioxidant is essential to improve the heat, oxygen and aging resistance of rubber. Reactive antioxidants are not easily pumped out by the oil.

5. Oil-resistant reclaimed rubber produces low-cost vulcanization formula for T-type sealing strips

80 parts of nitrile rubber, 20 parts of nitrile reclaimed rubber, 4.8 parts of zinc oxide, 1.2 parts of stearic acid, 1 part of antioxidant A, 50 parts of carbon black N774, 70 parts of light calcium, 15 parts of DBP, 5 parts of mineral oil, 0.4 parts of accelerator D, 1.4 parts of accelerator DM, sulfur, 2.2 parts; Total: 251 copies.

When using oil-resistant reclaimed rubber to produce T-type sealing strips, it is not only necessary to adjust the vulcanization formula, but also to adjust the production process parameters.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits