The initial rubber vulcanization is achieved through the sulfur in the production of rubber products, sulfur is the most commonly used vulcanizing agent, which can cross-link the rubber inside the linear macromolecular chains to form three-dimensional network space structure to improve the rubber Mechanical properties, chemical properties and so on. Sulfur vulcanization is often used in the production of rubber products using butyronitrile reclaimed rubber, however, sometimes there are problems with the use of sulfur. For example, a customer's telephone response recently said that nitrile reclaimed rubber is not well-vulcanized during the production of rubber products , While the increase in the amount of sulfur added smoke again after the phenomenon. Why is this?

In fact, in the actual production, different types of nitrile rubber reclaimed reclaimed rubber formulations vary in the amount of sulfur, too much dosage will affect the performance of reclaimed nitrile rubber products. As the nitrile rubber reclaimed less than the degree of unsaturation latex reclaimed rubber, so the amount of sulfur should be appropriately reduced: excessive use of sulfur will not only cause the hardness of nitrile rubber reclaimed products, reduced elongation at break, it will also cause frost The problem of smoke; the best amount of sulfur 1-2 parts, according to the different properties of rubber products increased or decreased appropriately.

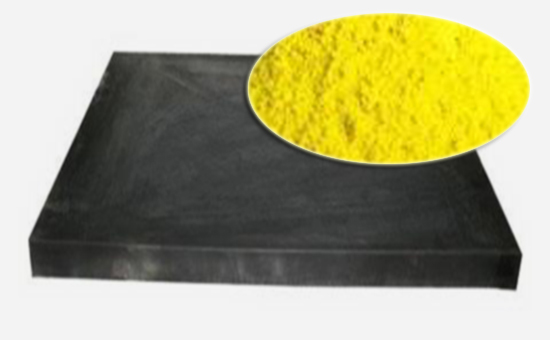

However, the amount of sulfur used in the reclaimed rubber products increases, leading to the smoking of the products, which is basically caused by the excessive use of sulfur. The sulfur itself is poorly dispersible in the reclaimed butyl rubber and the dosage is suddenly increased. , There will be dark brown spots. In addition, if you join the mill sulfur will damp agglomeration, resulting in excessive sulfur local consumption problems, it will lead to local smoke phenomenon. Therefore, the best sulfur stored in the mat or pad above, pay attention to waterproof moisture; if it has been caking before screening it, and then crushed sulfur broken.

Sulfur is the earliest vulcanizing agent used in the rubber industry and the most commonly used vulcanization system in the production of reclaimed rubber products. The use of nitrile reclaimed rubber to select sulfur vulcanization accelerators and activators can shorten the reaction time and reduce the amount of sulfur used, Produced nitrile rubber products reclaimed a good overall performance, especially the wear resistance and flex resistance. Improper use of sulfur can cause not only vulcanization or smoking of reclaimed nitrile rubber products, but also cause a series of other problems that need to be rationally added.

Hebei Hongyun reclaimed rubber professional technicians can answer various problems encountered in the production of reclaimed rubber products for free, including the amount of sulfur, various sulfide system design and other issues.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits