Oil-resistant hoses generally use nitrile rubber as the main raw material, or add an appropriate amount of neoprene and other polymers to obtain better comprehensive performance. In actual production, nitrile reclaimed rubber,can directly replace nitrile rubber or be used in combination with raw rubber to produce oil-resistant rubber hoses, effectively reducing the cost of raw materials. The physical properties of the glue are different, and different compounding agents are required.

1. Main points of compounding agent for the production of oil-resistant rubber hose with nitrile reclaimed rubber

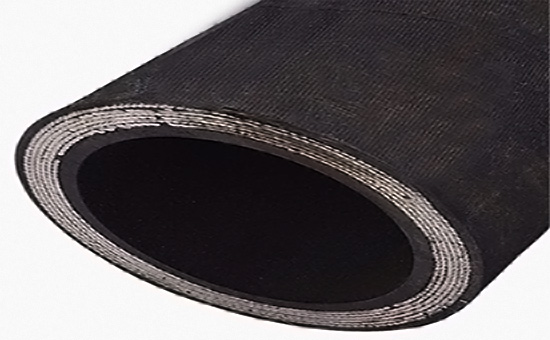

The outer rubber of the oil-resistant rubber hose belongs to the second working surface of the rubber hose and will be directly exposed to the use environment to protect the internal structure of the rubber hose from external wear, aging, corrosion, etc. The rubber material is required to have good wear resistance and tear resistance. The outer layer of the oil-resistant hose is generally made of nitrile rubber and neoprene rubber as the main raw materials. The appropriate amount of mixed nitrile reclaimed rubber can effectively reduce the cost of raw materials.

In actual production, when nitrile reclaimed rubber is used to produce oil-resistant hose cover, it is recommended to use sulfur-accelerator system or accelerator DM-TMTD system. The reinforcement system can be highly wear-resistant furnace black, semi-reinforced carbon black, etc., to improve the external wear resistance and tear resistance of oil-resistant hoses. Nitrile-butadiene reclaimed rubber oil-resistant hose cover softening and plasticizing system can use DOS, DBP, etc., or use together with aromatic oil, motor oil, heavy oil, etc. The use of anti-aging agents A, RD and paraffin can significantly improve the aging resistance of oil-resistant hoses.

2. Key points of rubber compounding agent in the production of oil-resistant rubber hose from nitrile reclaimed rubber

The middle layer glue of the oil-resistant hose is filling glue and intermediate glue, which can fill, bond the skeleton and the glue layer, buffer, reduce friction, fatigue and heat generation. , generally processed with nitrile rubber as the main raw material; nitrile reclaimed rubber can be used together with nitrile raw rubber to produce oil-resistant rubber hose middle layer rubber to reduce costs.

When nitrile reclaimed rubber is used to produce oil-resistant rubber hose, a sulfur-accelerator system is often used, and thiazole accelerators and sulfenamide accelerators are commonly used, such as accelerator CZ. It is reinforced with high wear-resistant carbon black, semi-reinforced carbon black or silica, and filled with inorganic fillers such as calcium carbonate to improve the physical and mechanical properties of the rubber in the nitrile reclaimed rubber oil-resistant hose. It is recommended to use petroleum-based softeners for softening and plasticizing systems in the formulation of nitrile reclaimed rubber oil-resistant hoses, such as aromatic oil, heavy oil, asphalt, etc., together with solid softeners; if necessary, add adhesive softening plasticizers, such as coumarone resin, Rosin, or RF, RH direct bonding system.

3. The key points of the inner rubber compounding agent for the production of oil-resistant rubber hose from nitrile reclaimed rubber

The inner layer of the oil-resistant hose is the first working surface of the hose to transport the medium. It has harsh operating conditions and requires certain elasticity, flexibility, adaptability to oil media, swelling resistance and aging resistance. It is processed with nitrile rubber as the main raw material. It is made of nitrile reclaimed rubber mixed with an appropriate amount. From the point of view of process performance, the nitrile oil-resistant rubber hose requires the semi-finished product to have sufficient stiffness, small shrinkage, and smooth extruded and calendered surfaces. It is recommended to choose high-quality nitrile reclaimed rubber with high nitrile content and high fineness.

When nitrile reclaimed rubber is used to prepare the inner layer of oil-resistant hoses, sulfur-accelerator systems are often used, such as accelerators TMTD, CZ, etc. Reclaimed rubber oil-resistant hose inner rubber reinforcement filling system can use high wear-resistant furnace black, semi-reinforced carbon black, general-purpose carbon black, calcium carbonate, clay, high clay, etc. To improve the processing performance of rubber and reclaimed rubber for oil-resistant hoses, it is recommended to use aromatic oil, heavy oil, motor oil, pine tar and solid softeners such as asphalt, petroleum resin, etc. To improve the aging resistance of the inner rubber of the reclaimed rubber oil-resistant hose, it is recommended to use amine anti-aging anti-aging agents such as anti-aging agents A and RD.

When using reclaimed rubber to produce oil-resistant hoses, the outer rubber, middle rubber, and inner rubber must be selected according to the actual performance requirements of the rubber material.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits