The raw materials of EPDM reclaimed rubber are EPDM head glue, unvulcanized EPDM rubber and waste EPDM rubber products such as EPDM sealing strips, which are made by crushing, desulfurization, refining and other processes, and have the performance characteristics of high and low temperature resistance, ozone resistance, weather resistance, etc., and can be used alone or in combination with EPDM rubber, butyl rubber, etc. to produce construction rubber products, effectively reducing production costs.

1. Application of EPDM reclaimed rubber in building sealing materials

(1) Rubber sealing strip: It is an important material in the sealing of building doors and windows by generating contact pressure through the elasticity of the lip, cavity, flange and other parts and the surface of the contact object. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, and can be used alone or in combination with EPDM rubber, butyl rubber, butyl reclaimed rubber, etc. to produce building door and window sealing strips, reducing the cost of raw materials under the premise of ensuring the tensile strength, hand elasticity, aging resistance and other requirements of the sealing strip.

(2) Pipeline seals: rubber products used for pipeline connection parts to prevent leakage of fluids (such as liquids, gases, etc.), with good elasticity and sealing performance, can adapt to the expansion and deformation of pipelines due to temperature changes, etc., and ensure the tightness and stability of pipeline systems. EPDM reclaimed rubber has good weather resistance, chemical corrosion resistance and low compression set, and can be used with EPDM original rubber to produce pipeline seals, and the finished product has good resistance to a variety of chemicals (such as acid, alkali, salt, etc.), and maintains a low compression set rate under long-term pressure to ensure the durability of the sealing effect.

2. Application of EPDM reclaimed rubber in building waterproof materials

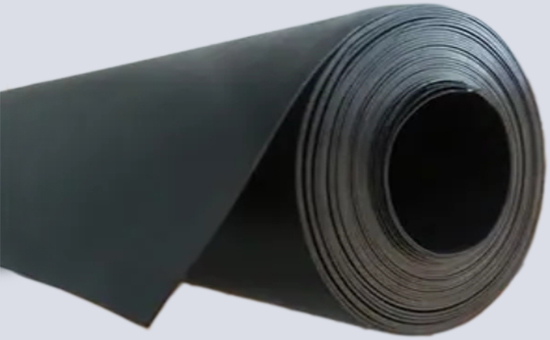

(1) Rubber waterproofing membrane: It is a large-area sheet rubber product processed from rubber as the main raw material, which is widely used in roofs and underground to effectively prevent the leakage of rainwater, groundwater or other liquids, and protect building structures or related facilities from water erosion. EPDM rubber has better weather resistance and ozone resistance than neoprene E4LYY910 and butyl rubber, and is an ideal raw material for the production of waterproof membranes. The appropriate use of EPDM reclaimed rubber in EPDM rubber waterproofing membrane can reduce the cost of raw materials on the premise of ensuring the performance of the finished product. EPDM reclaimed rubber can also be used in combination with butyl reclaimed rubber to produce more cost-effective building waterproofing membranes.

(2) Rubber waterstop: made of rubber as the main raw material through plastic refining, mixing, pressing and molding processes, with good elasticity, wear resistance, aging resistance, tear resistance and other performance characteristics, is widely used in construction engineering, traffic engineering, water conservancy engineering and other fields. EPDM reclaimed rubber can be used alone or combined with EPDM original rubber to produce rubber waterstops, reducing raw material costs and production energy consumption.

3. Application of EPDM reclaimed rubber in other building materials

(1) Heat-resistant rubber plate: It needs to be used at a higher temperature for a long time, and the rubber material is required to have good heat resistance, and it is generally processed from butyl rubber and ethylene propylene rubber as raw materials. EPDM reclaimed rubber can be used alone or combined with butyl rubber and ethylene propylene rubber to produce heat-resistant rubber sheets to reduce costs.

(2) Rubber joints: flexible connectors connecting pipelines, in the pipeline systems of large buildings and important facilities, EPDM reclaimed rubber can partially replace raw materials for the production of rubber joints. Under the condition of ensuring that the original physical performance indicators such as absorbing vibration, reducing noise and compensating displacement remain unchanged, the cost of raw materials is reduced.

In actual production, EPDM reclaimed rubber can also be used in the processing of rubber products such as sealing paste, insulation materials, insulating and shock-absorbing pads, and will be followed by sharing with you the vulcanization formula and formula design points of different types of building rubber products produced by EPDM reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits