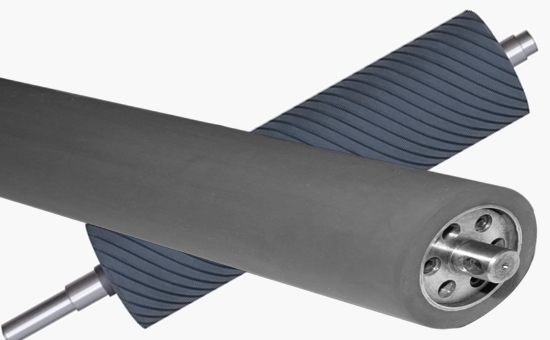

EPDM rubber has excellent high and low temperature resistance and anti-aging properties. EPDM rubber rollers can be used under high temperature conditions of 150°C and are often used in plastic machinery, tanning machinery and other fields. The performance requirements of EPDM rubber rollers in different applications are different, and the types of rubber raw materials and compounding agents used vary greatly. Manufacturers need to choose appropriate rubber raw materials according to actual needs.

1. Reference formula for general EPDM rubber rollers

100 parts of EPDM rubber, 65 parts of carbon black, 45 parts of paraffin oil, 5 parts of zinc oxide, 1 part of stearic acid, 7 parts of dicumyl peroxide, 2 parts of ethylene dimethacrylate; total : 225 copies.

2. Skills for selecting rubber raw materials for EPDM rubber rollers

EPDM rubber rollers have high elasticity, heat resistance and aging resistance, and have greater resistance to alcohols, acids, strong alkalis, oxidants, ketones and certain esters. They are widely used in printing rubber rollers and papermaking rubber rollers. , Ink rollers and other products are in production. When preparing rubber rollers with EPDM rubber 2YLYY621 as the main raw material, appropriate use of EPDM reclaimed rubber, which is close to the basic indicators of rubber rollers, can improve the production process of rubber rollers and reduce the cost of raw materials.

In actual production, a small amount of butyl rubber or butyl reclaimed rubber can be added to the EPDM rubber/reclaimed rubber roller formula to further improve the heat resistance and chemical stability of the EPDM rubber roller.

3. Selection skills of rubber accessories for EPDM rubber rollers

When EPDM virgin rubber and EPDM reclaimed rubber are used together to produce rubber rollers, choosing appropriate rubber additives can significantly improve the production process of the rubber roller and the performance of the finished product. The EPDM rubber roller vulcanization system uses DCP and methacrylate resin together to give the vulcanized rubber roller excellent compression set and heat aging resistance. Choosing to soften the paraffin oil with good compatibility with the peroxide curing system can further improve the rubber processing technology.

When using carbon black N550 for reinforcement, the reinforcement effect is good, and it can give the EPDM compound higher stiffness, high temperature resistance, and thermal conductivity. EPDM rubber has low density and can use a large amount of rubber oil and fillers, effectively reducing the production cost of rubber rollers. In actual production, if you want to reduce the production cost of EPDM rubber rollers, the editor recommends the use of reclaimed rubber. Later, I will have the opportunity to continue to share with you the application of recycled rubber in EPDM rubber rollers.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits