Natural rubber soles have excellent abrasion resistance, elasticity and water resistance, and are widely used in various types of footwear products. However, the price of natural rubber is high and it is greatly affected by market fluctuations, which makes many rubber products enterprises face cost pressure in the production process. In order to reduce the production cost of natural rubber soles, enterprises can consider using the following four option raw materials: latex reclaimed rubber, tire reclaimed rubber, reclaimed rubber powder and floor natural rubber.

1. Latex reclaimed rubber

Latex reclaimed rubber is a recycled rubber processed from waste natural rubber and waste latex products, which has the basic performance characteristics of natural rubber, good elasticity, high strength and good wear resistance, and can directly replace natural rubber for sole production and reduce production costs.

When using latex reclaimed rubber to reduce the cost of rubber products, rubber product manufacturers can choose the appropriate latex reclaimed rubber according to the color of the sole and the requirements of physical performance parameters, and appropriately adjust the amount of latex reclaimed rubber in the formula. For example, white or light-colored soles can choose white latex reclaimed rubber, which is easy to match and not easy to change color; Black latex reclaimed rubber can be used for the black sole to further reduce costs.

2. Tire reclaimed rubber

Tire reclaimed rubber is a recycled rubber made of waste tire rubber through crushing, desulfurization, refining and other processes, which has high wear resistance and anti-aging performance. The appropriate amount of tire reclaimed rubber in the production of natural rubber soles can reduce the cost of raw materials and improve the performance of rubber processing technology on the premise of ensuring the performance of shoe soles. The vulcanization performance of tire reclaimed rubber E4LYY528 is similar to that of natural rubber, but the vulcanization system needs to be adjusted appropriately to ensure the best cross-linking effect. The addition of reclaimed rubber can reduce the vulcanization and regression of natural rubber.

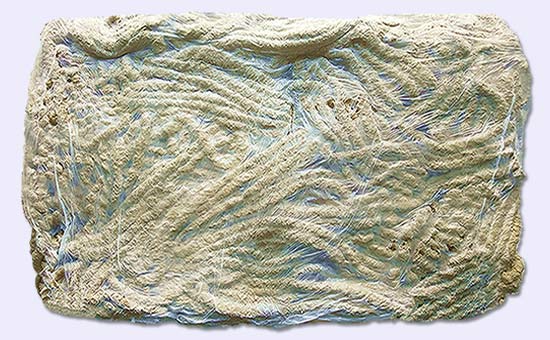

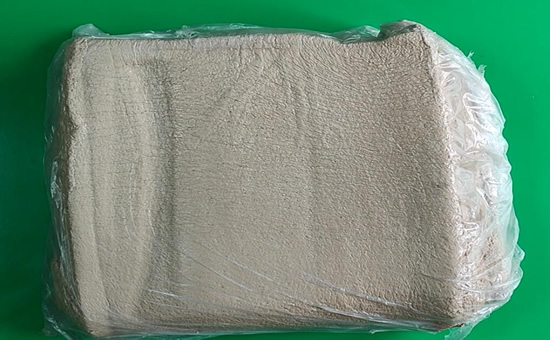

3. Reclaimed rubber powder

Reclaimed rubber powder is a fine rubber particle made by crushing and grinding waste rubber products, which has good dispersion and processing properties. White lightweight latex powder has the characteristics of light color, high fineness, small specific gravity and good elasticity, which can reduce the specific gravity in the production of light-colored natural rubber soles. Tire rubber powder is inexpensive, used in the production of black natural rubber soles can reduce the amount of raw rubber, under the premise of ensuring the use of performance, the amount of tire rubber powder can even reach more than 100 copies, reduce costs.

4. Floor-to-ground natural rubber

The tensile strength, elongation at break and other physical indicators of natural rubber are almost the same as those of natural rubber, and the replacement of natural rubber for the production of soles can effectively reduce production costs on the premise of ensuring product performance, while maintaining the elasticity and wear resistance of the sole.

In the production of natural rubber soles, choosing the right latex reclaimed rubber, tire reclaimed rubber, reclaimed rubber powder or landing natural rubber can significantly reduce the production cost on the premise of ensuring the basic performance of the sole, and at the same time improve the processing technology performance of rubber sole, reduce production energy consumption and improve the yield rate. In the future, Xiaobian will share with you the key points of the production process of natural rubber soles mixed with low-cost rubber raw materials and the vulcanization formula of low-cost rubber soles.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits