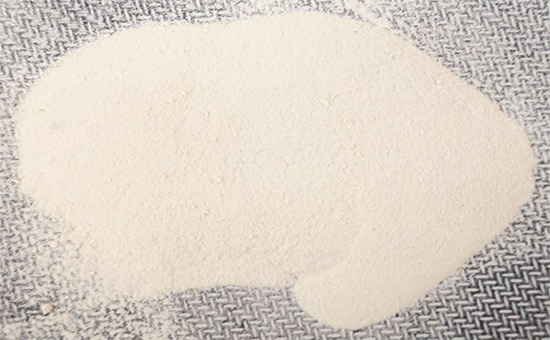

Rubber powder processed from waste rubber and waste rubber products can be used as the main material in the production of rubber products, and can also be used as an organic filler, effectively reducing raw material costs. When using rubber powder in the production of rubber products, the dispersion of rubber powder in rubber directly affects the quality of finished rubber products. Increasing the dispersion of rubber powder in rubber can increase the amount of rubber powder and reduce the cost while optimizing the rubber powder Comprehensive index of rubber products.

1. Reasonable use of dispersant to improve the dispersion of rubber powder in rubber

Rubber dispersant is a commonly used operation aid in the processing of rubber products, which can promote the uniform dispersion of powdered compound in the rubber compound. When using rubber powder in rubber products, proper use of dispersant can not only promote the uniform dispersion of rubber powder in the rubber compound, but also uniformly mix rubbers of different polarities, effectively improve the plasticity, fluidity and dimensional stability of rubber products. Shorten the scorch time, reduce the generation of air bubbles, to a certain extent, improve the vulcanization rubber's anti-vulcanization reversion performance and scorch safety.

In different varieties of rubber products, the amount of rubber dispersant can be controlled between 1.5-3 parts, the specific amount is adjusted according to the type and amount of raw materials.

2. Reasonable use of leveling agent to improve the dispersion of rubber powder in rubber

The leveling agent is a mixture of low molecular weight resins of different polarities. The main role in the production of rubber products is to solve the problem of blending polymers of different polarities. It can be similar to the two rubbers with poor compatibility. The role of solvents. When using rubber powder in the production of rubber products, an appropriate amount of leveling agent can improve the dispersion of rubber powder in rubber, and then improve the filling effect of rubber powder and improve the self-adhesiveness of rubber. This is in rubber products containing skeleton materials. especially important.

3. Reasonable use of softeners to improve the dispersion of rubber powder in rubber

Rubber softener can soften rubber material, improve rubber plasticity, and promote the uniform dispersion of 2LLYY428 in the production of rubber products. When using rubber powder in rubber products to reduce the cost of raw materials, an appropriate increase in the amount of softener can further improve the dispersion of rubber powder in rubber, thereby improving the overall performance of rubber products.

4. Use activated rubber powder instead of vulcanized rubber powder to improve the dispersion of rubber powder

The surface properties of rubber powder affect its dispersibility in rubber products. After the surface modification (such as gas modification, graft modification, etc.), a large number of molecular chains in the activated rubber powder are destroyed, and new active groups generated on the surface can solve the problem of the transition layer between the rubber powder and the matrix rubber, The rubber has better compatibility and adhesion, and can be uniformly dispersed in the rubber, and then improve the mechanical properties of rubber products by increasing the cross-linking density of the rubber compound.

In theory, the higher the fineness of the rubber powder, the better the dispersibility in the rubber. The rubber powder can be sieved and dried before use to avoid the presence of large particles or volatile substances in the rubber powder to affect its dispersion in rubber. When using rubber powder to reduce the production cost of rubber products, rubber product manufacturers must choose the appropriate variety and fineness of rubber powder, and further improve the dispersion of rubber powder in rubber by adjusting the formula, while reducing costs and further improving the comprehensive index of rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits