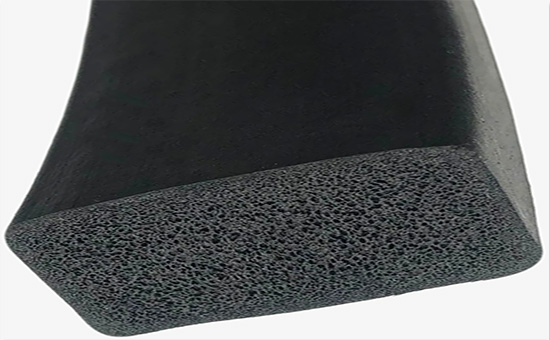

Sponge rubber eyelets cover the whole material, featuring small density, elasticity and flexibility. When in use, the effect of shock absorption, sound insulation and heat insulation is remarkable. When using recycled rubber to prepare low-cost sponge rubber products, the rubber compound needs to meet certain requirements, specifically in plasticity, matching of foaming rate and curing rate, heat transfer, pressure and special performance requirements. Xiao Bian will discuss with you today in detail the five requirements that must be met by the rubber compound when using recycled rubber to prepare sponge rubber.

1. Recycled rubber or recycled rubber/raw rubber blend has proper plasticity

Suitable plasticity is the basic condition for preparing sponge rubber from recycled rubber. The plasticity of recycled rubber is closely related to the density of sponge rubber, the structure and size of pores, and the starting ratio, which is generally controlled above 0.5 (Wechsler plasticity). Compared with the original rubber, the reclaimed rubber has better plasticity and is easy to be plasticized. When the recycled rubber/raw rubber is used to produce sponge rubber products, especially when it is used with natural rubber, nitrile rubber and other raw rubbers with higher Mooney viscosity, special attention must be paid to the plasticity of the raw rubber. It is recommended to use three or four stages of plasticizing, with the number of thin passes up to 40-60 times.

2. The foaming rate of recycled rubber compound matches the curing rate

3. The pressure generated inside the rubber when the recycled rubber foams shall be greater than the external pressure

Use recycled rubber to prepare sponge rubber products, such as sponge shoe soles, sponge rubber plates, etc. If the curing speed is too slow, the foaming speed is too fast, and the foaming pressure is too low, the bubbles generated by the foaming agent are easy to diffuse out of each hole; If the curing rate is too fast or the decomposition rate of the foaming agent is too slow, the foaming pressure is too high and it is difficult to foam. Because the foaming speed is difficult to control, the curing system and curing temperature can be adjusted to match the foaming speed; The vulcanization speed of the reclaimed rubber can be adjusted in a wide vulcanization period at a certain vulcanization temperature to avoid excessive influence of temperature fluctuation on the foaming speed and vulcanization speed.

It is suggested that the accelerator with slow curing rate and accelerator with fast curing start should be used together when the reclaimed foam rubber is vulcanized with sulfur curing system. Peroxide vulcanization has the characteristics of fast vulcanization start and slow vulcanization speed. When the reclaimed rubber 2ELYY1012 sponge rubber is vulcanized with peroxide, the vulcanization foaming process is easy to control; The decomposition temperature of the peroxide should match the decomposition temperature of the foaming agent. The curing rate can be adjusted by adjusting the amount of crosslinking agent.

4. The heat transfer of the recycled rubber compound is better, so that the inner and outer blast holes are uniform and the vulcanization degree is consistent.

5. Select appropriate recycled rubber according to the special performance requirements of sponge rubber products

In actual production, latex reclaimed rubber, tire reclaimed rubber, styrene butadiene reclaimed rubber, butadiene butadiene reclaimed rubber, etc. can be used to prepare ordinary sponge rubber from reclaimed rubber; To prepare oil resistant sponge rubber, nitrile reclaimed rubber is an ideal raw material, and neoprene reclaimed rubber can also be used appropriately when necessary; When the heat resistance and ozone resistance of recycled rubber sponge are strictly required, it is recommended to use EPDM recycled rubber.

When producing sponge rubber products with recycled rubber as the main raw material, the rubber product manufacturer must ensure that the rubber meets the above five requirements. Later, Xiaobian will continue to share with you the formula design skills of recycled rubber sponge rubber, the vulcanization formula of recycled rubber sponge rubber and the key points of production process.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits