Only adding a vulcanizing agent to the reclaimed rubber and having a cross-linking reaction with it to produce a three-dimensional three-dimensional network structure can be of use value. Sulfur is the most commonly used vulcanizing agent in the production of reclaimed rubber products. There are six main types of sulfur used in the rubber industry: sulfur powder, precipitated sulfur, insoluble sulfur, colloidal sulfur, sulfur mixture and surface-treated sulfur, among which sulfur powder and insoluble sulfur are the most used. When using reclaimed rubber to produce rubber products, is it better to use sulfur powder or insoluble sulfur?

1. Tips for using ordinary sulfur powder in reclaimed rubber products

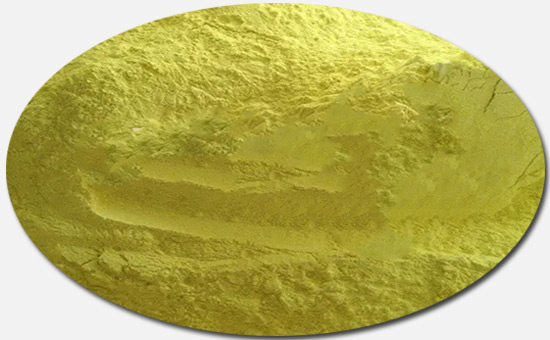

Ordinary sulfur powder is made from sulfur block, yellow powder, insoluble in water, slightly soluble in ethanol, ether, soluble in carbon dioxide, carbon tetrachloride and benzene. It is the most widely used variety in the production of rubber products, mainly for vulcanization. , to enhance the physical properties of rubber. Based on 100 parts of raw rubber, the amount of sulfur in general soft rubber should not exceed 0.2-5 parts, the amount of sulfur in semi-hard rubber should be controlled among 10-30 parts, and the amount of sulfur in hard rubber can be increased to 25-50 servings.

It should be noted that: when the reclaimed rubber product is vulcanized with ordinary sulfur powder, the solubility of sulfur in the reclaimed rubber increases with the increase of temperature; when the temperature decreases, the sulfur will crystallize out of the rubber. Therefore, it is necessary to reasonably control the amount of sulfur in the formulation of reclaimed rubber 2ELYY916 products, otherwise the compounding amount of sulfur in the rubber compound exceeds its solubility and reaches supersaturation, which will "bloom", destroying the uniformity of sulfur dispersion in the rubber compound, making the surface of the rubber compound Adhesion decreases, making processing difficult.

2. Tips for using insoluble sulfur in reclaimed rubber products

Insoluble sulfur is a sulfur polymer, macromolecular polymerization sulfur: heat α-sulfur to high temperature (close to the boiling point), when it becomes a dark brown viscous liquid, it will polymerize into insoluble sulfur after cooling rapidly; or spray superheated sulfur steam into cold water quickly. Cooled to below 90 ℃ obtained. Insoluble sulfur is insoluble in rubber and can be evenly dispersed in the reclaimed rubber compound to better ensure the quality of process operation and the uniformity of vulcanized cross-links in the product.

Insoluble sulfur exists in a dispersed state in the rubber, which can effectively prevent the rubber from spraying sulfur, and is not prone to early vulcanization during processing. At the same time, the reclaimed rubber compound can maintain a good viscosity. It should be noted that insoluble sulfur will also become ordinary sulfur if it is not stored properly.

3. Comparison of the solubility of sulfur powder and insoluble sulfur in reclaimed rubber

The solubility of ordinary sulfur in reclaimed rubber is about 1%, and the sulfur powder that exceeds its solubility will be sprayed out of the surface after the rubber is cooled. The insoluble sulfur is not restricted by the solubility in the reclaimed rubber, and the rubber material does not bloom during the storage period, and its activity is greater than that of ordinary sulfur powder. When reclaimed rubber products require a higher amount of sulfur, it is recommended to use insoluble sulfur to avoid blooming of rubber products.

4. Adding skills of sulfur powder and insoluble sulfur in reclaimed rubber

In actual production, insoluble sulfur can be directly added to the rubber compound during the mixing of reclaimed rubber, while ordinary sulfur powder is recommended to be added on the cold roll of the open mill, preferably after other compounding agents are added. Insoluble sulfur can be added on the mixer, but it should be added under the condition that the temperature is lower than 90 ℃ before degumming; when the temperature is higher than 90 ℃, too long time will cause the conversion of insoluble sulfur to ordinary soluble sulfur. In addition, thiazole accelerators can increase the risk of common sulfur blooms.

Is ordinary sulfur powder or insoluble sulfur used in the production of reclaimed rubber products? This is all determined according to the performance requirements of rubber products. Correct selection of sulfur varieties, reasonable determination of the amount of sulfur, and mastery of the timing of adding sulfur can further improve the quality of reclaimed rubber products. Later, the editor will continue to share relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits