The change in structure and properties of rubber under dynamic tension, compression, shear or bending is called "fatigue", and fatigue resistance is designed to maintain the physical and mechanical properties of the original design for a long time. When using butyl rubber to produce rubber products, improving the fatigue resistance of rubber compounds can delay the service life of rubber products, and the fatigue resistance of butyl rubber can generally be improved from the selection of rubber compounds and the design of the matching system.

1. Butyl rubber is used in combination with other rubbers to improve the fatigue resistance of rubber compounds

Butyl rubber isobutylene and a small amount of isoprene are copolymerized, which has excellent air tightness, damping, aging resistance and chemical stability. When using butyl rubber as the main raw material to produce rubber products, choose to use it with appropriate varieties of rubber raw materials, moderately increase the crystallization amount in the system, and make the strong and weak bonds properly combined, which can significantly improve the fatigue life of butyl rubber, and the following two methods are common:

(1) Add 3-8 parts of neoprene to butyl rubber, and the tensile fatigue performance is significantly improved;

(2) Adding an appropriate amount of butyl reclaimed rubber to butyl rubber can significantly increase the fatigue life.

2. Reasonable design of the matching system to improve the fatigue resistance of butyl rubber

(1)In addition, fatigue conditions are related to the amount of crosslinker used. Appropriately increasing the amount of crosslinker can improve the fatigue aging resistance of butyl rubber vulcanized rubber to a certain extent.

(2) Packing system: the choice of carbon black with high structure can improve the fatigue and destructive resistance of butyl rubber vulcanized rubber; The larger the particle size of the inert filler, the larger the filling amount, and the worse the fatigue resistance of the vulcanized adhesive.

(3) Softening system: most softening plasticizers will reduce the fatigue and destructive resistance of rubber vulcanized rubber, especially softeners and plasticizer.Butyl rubber uses liquid 1,2-PBD, which can participate in the sulfur/accelerator vulcanization reaction, as a softener, which can improve fatigue life.

with low viscosity and dilution effect on rubber. The selection of fatigue-resistant rubber softening plasticizers follows two principles: one is to select non-viscous softening plasticizers with low softening points as much as possible; Second, the amount of softening plasticizer should be as much as possible, but the amount of reactive softening plasticizer should not be too much.

To improve the fatigue aging resistance of butyl rubber products, rubber product manufacturers also need to reasonably select anti-aging system compounds; When choosing to use it in combination with other rubbers, it is recommended to use butyl reclaimed rubber.

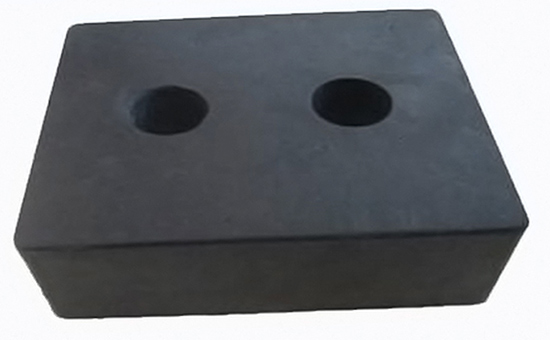

Butyl reclaimed rubber is a rubber material prepared by physical and chemical treatment of waste butyl rubber products, which retains many of the original characteristics of butyl rubber, including air tightness, aging resistance and chemical resistance, and the price is lower than that of butyl rubber, which is used in the production of tire inner tubes, vulcanized capsules, seals, shock-absorbing materials, pharmaceutical bottle stoppers, tapes and hoses and other rubber products, which can not only reduce the cost of raw materials, but also improve the fatigue aging resistance of rubber, and also help to reduce the environmental impact of waste rubber and meet the dual needs of economic benefits and environmental protection. is a sustainable material choice.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits