Nitrile Rubber Encyclopedia

-

Nitrile recycled rubber is an important recycled rubber material with excellent oil resistance and a wide range of applications in the rubber products industry. In the production process of nitrile reclaimed ru…

-

As a low-cost option raw material for nitrile original rubber, nitrile reclaimed rubber can be used alone or combined with nitrile rubber to produce high-elastic and oil-resistant rubber pads; Rational design o…

-

Nitrile reclaimed rubber is processed from waste nitrile rubber products such as nitrile gloves as raw materials, or an appropriate amount of sub-brand nitrile butadiene rubber is added, the product has good oi…

-

To produce NBR oil-resistant sealing strips black solid round strips from NBR reclaimed rubber, we must first select the appropriate raw materials and formulas, pay attention to the dosing sequence of the compo…

-

The vulcanization formula of rubber-coated rubber miscellaneous parts in the production of nitrile oil-resistant reclaimed rubber was analyzed and optimized, multiple key parameters of cost measurement were dis…

-

Recycled nitrile rubber is a new material with high quality and low price, which has the characteristics of reducing specific gravity and improving oil resistance. Oil-resistant rubber liner mixed with recycled…

-

The oil-resistant and wear-resistant rubber sheet produced by nitrile reclaimed rubber has excellent oil, wear, weather resistance and other properties, and is suitable for various industrial fields that need t…

-

Nitrile regeneration rubber production oil-resistant and wear-resistant mud pipe inner wall glue vulcanization formula is a complex process, need to choose the right nitrile regeneration rubber for scientific p…

-

The skeletonless oil-resistant sealing gasket is a sealing part made of nitrile recycled rubber, which has excellent oil resistance and sealing performance in high temperature and high pressure environments. Ni…

-

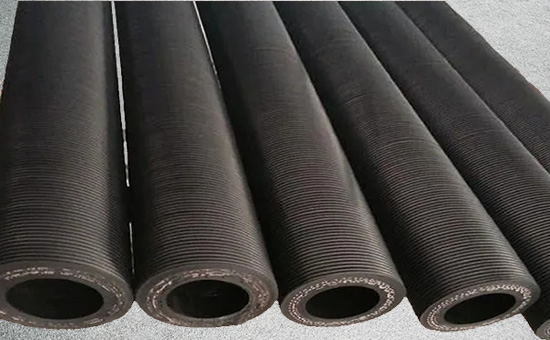

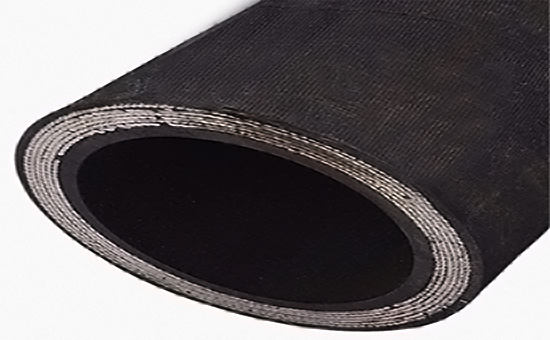

Nitrile recycled rubber has good environmental performance, high resource utilization, reduces oil demand and reduces waste generation. The production process of oil-resistant rubber tubing includes batching, m…

-

Nitrile reclaimed rubber production rotary shaft lip sealing ring has the advantages of good environmental performance, strong oil resistance, good wear resistance, good acid and alkali resistance, and low cost…

-

R-NBR has excellent thermal stability, aging resistance, oil and chemical resistance, tensile strength and tear strength, processability, wear resistance and flex fatigue resistance; can reduce raw material cos…

-

The oil-resistant rubber plug produced by R-NBR has excellent oil resistance and sealing performance, and its elasticity is slightly worse than that of NBR, but it has a huge price and cost advantage. Since R-N…

-

Nitrile regenerated rubber has the characteristics of oil resistance, good thermal performance, high chemical stability, and low elastic coefficient, and is widely used in the production of O-type oil-resistant…

-

When using nitrile rubber to reduce the production cost of white and light colored rubber products, it is recommended to use white reinforcing fillers. White carbon black has the best reinforcing effect in the …

-

After vulcanization, butadiene rubber has excellent cold resistance, wear resistance, and elasticity. Therefore, it can be combined with an appropriate amount of butadiene rubber to improve the comprehensive pe…

-

The sulfur vulcanization system is most widely used in nitrile rubber products. When using nitrile rubber/nitrile recycled rubber and using rubber to produce rubber products, how to design a more reasonable vul…

-

Nitrile rubber has excellent oil resistance and is an ideal raw material for producing oil resistant rubber tubes. The reclaimed nitrile rubber retains the basic properties of the original nitrile rubber, and i…

-

Recycled nitrile rubber can be used alone or in combination with nitrile rubber to produce various oil-resistant and wear-resistant rubber products, such as wear-resistant parts, effectively reducing raw materi…

-

Nitrile reclaimed rubber can be used alone or in combination with nitrile rubber to produce various oil-resistant rubber products, such as oil-resistant washers, gaskets, oil seals, oil-resistant rubber shoes, …