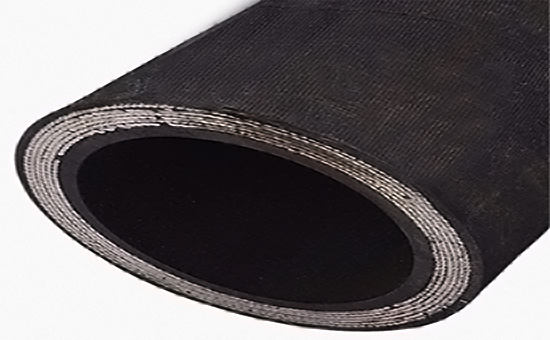

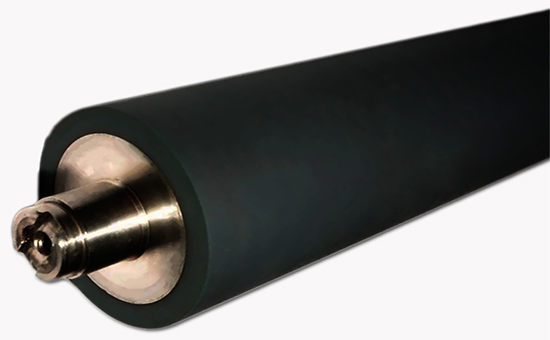

The reclaimed nitrile rubber retains the basic performance characteristics of nitrile rubber, with high oil resistance coefficient, wear resistance and aging resistance. It can be used alone or in combination with nitrile rubber to produce various oil-resistant rubber products, such as oil-resistant rubber tubes, oil-resistant seals and wear-resistant rubber products, such as wear-resistant parts, effectively reducing the production of raw materials on the premise of ensuring product quality. When using nitrile rubber to produce rubber products, reasonable design of reinforcing and filling system can further optimize the quality of recycled rubber products.

Carbon black is the most commonly used compound in the reinforcing and filling system of nitrile rubber products, and proper addition of carbon black can play a reinforcing and filling role. Carbon black for rubber mainly includes super wear-resisting carbon black, medium and super wear-resisting carbon black, high wear-resisting carbon black, quick-pressing carbon black, universal carbon black, semi-reinforcing carbon black, etc. According to the reinforcing effect of carbon black on rubber, it can be divided into hard carbon black and soft carbon black, in which hard carbon black has a strong reinforcing effect on nitrile rubber, and soft carbon black plays a filling role.

When using nitrile rubber, nitrile rubber/nitrile rubber to produce ordinary oil-resistant rubber products, the rubber compound is required to have good oil resistance, aging resistance, necessary physical and mechanical properties and certain compression permanent deformation resistance. It is recommended to use reinforced carbon black or use reinforced carbon black together with other carbon black. When using nitrile rubber 2SLYY36 to produce rubber products with requirements for strength, elongation and wear resistance, it is recommended to use high strength carbon black, medium and super wear carbon black and other high strength carbon black. Coarse particle soft carbon black can be used when producing rubber products with high resilience requirements using nitrile rubber.

In actual production, the reclaimed nitrile rubber product can be added with 50-60 parts of high wear-resisting carbon black, 60-100 parts of semi-reinforced carbon black, and about 50 parts of trough carbon black, giving the reclaimed nitrile rubber vulcanizate better mechanical properties.

The commonly used fillers in the reinforcing and filling system of nitrile rubber products include calcium carbonate (light calcium carbonate and active calcium carbonate have better filling effect), clay, magnesium oxide, etc. When used in the compatibilization of nitrile rubber products, a large amount of calcium carbonate can be filled to reduce the cost of more raw materials. When calcium carbonate and active reinforcing agent are used together in the reinforcing and filling system of NBR reclaimed rubber, it can not only improve the processing performance of rubber compound, but also improve the physical and mechanical properties of vulcanizate. It should be noted that the clay has large elasticity, large permanent deformation and will delay vulcanization. The amount of clay used in nitrile rubber products should be reasonably controlled.

Nitrile butadiene rubber can be used for oil resistant pipes, oil seals, rubber rings, oil resistant rubber pads, oil resistant rubber shoes, rubber diaphragms, O-rings, leather cups, oil resistant rubber pads, wear-resistant parts and other rubber products. The performance requirements of rubber products in different applications are different, and it is necessary to reasonably design the vulcanization system, reinforcement filling system, softening and plasticizing system, anti-aging system, etc. in the formula, Later, the editor will continue to share with you the design points of other coordination systems of nitrile rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits