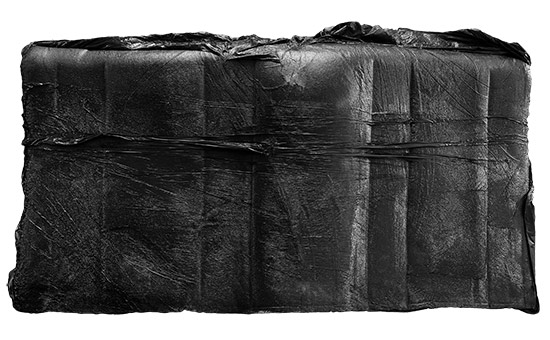

Nitrile reclaimed rubber has excellent oil resistance, good wear resistance and aging resistance, and can replace nitrile rubber in whole or in part to produce molded oil-resistant and wear-resistant rubber products, reducing costs on the premise of ensuring product performance. When using nitrile reclaimed rubber or nitrile rubber/reclaimed rubber combined with rubber to produce molded rubber products, it is necessary to select the appropriate nitrile reclaimed rubber according to the specific needs of the product, reasonably determine the proportion of reclaimed rubber, and appropriately adjust the production formula.

1. Application of nitrile reclaimed rubber in common molded rubber products

Nitrile reclaimed rubber can be used alone or in combination with nitrile rubber to produce molded rubber sealing products, such as sealing rings, oil seals, gaskets, diaphragms, etc; Nitrile reclaimed rubber can also be used to produce industrial E4LYY624 parts, such as small rubber rollers, leather bowls, wear-resistant parts, valve gaskets, and hard rubber parts with high mechanical strength such as gears and bearings; The oil-resistant sole is mixed with nitrile reclaimed rubber, which can effectively reduce the cost of raw materials.

2. Characteristics of the formula of nitrile reclaimed rubber for the preparation of molded rubber

(1) Large plasticity, before the start of vulcanization, the rubber material is easy to flow in the model, and can be evenly fused together; Compared with nitrile rubber, nitrile reclaimed rubber has better plasticity and fluidity.(2) It is not easy to scorch after cross-linking, and the storage time is long.(3) The vulcanization speed is fast, and the rubber material can achieve good positive vulcanization in a short time, shorten the vulcanization cycle, and improve the utilization rate of the model.(4) The compression deformation of the rubber material is small, and the aging resistance is good.

3. Formula design for the production of molded rubber products by nitrile reclaimed rubber

When using nitrile reclaimed rubber as the main raw material to produce molded rubber products, the design of the vulcanization system must comprehensively consider the molding vulcanization method, vulcanization conditions (temperature and time), storage time of the rubber compound, product performance requirements and other aspects to find a balance. Nitrile reclaimed rubber molded products mostly use sulfur vulcanization system, and the accelerator TS is commonly used with sulfur, and the amount of sulfur is controlled among 1-2 parts.

In order to increase the fluidity of the rubber compound, a small amount of lubricant can be added to the formula of nitrile reclaimed rubber molded products; Reasonable control of the amount of lubricant, too much will spray out the surface of the rubber compound, hindering the fusion of the rubber during molding.In the preparation of nitrile reclaimed rubber molded rubber compounds, rubber product manufacturers also need to choose appropriate reinforcing agents, fillers, softeners, plasticizers, antioxidants, etc., and discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits