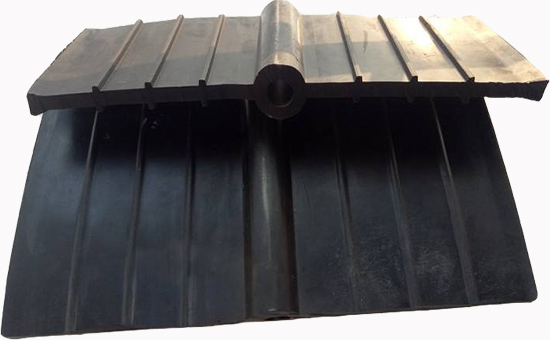

The rubber waterstop is mainly used in underground projects, tunnel culverts, water transfer aqueducts, dams and other basic projects. The main raw materials are natural rubber, neoprene and EPDM rubber, of which EPDM rubber is resistant to high and low temperature. Excellent aging resistance, the rubberized waterstop produced has a long service life. The design of the vulcanization system in the EPDM waterstop formulation not only affects the comprehensive index of the waterstop, but also affects the production efficiency of the rubber waterstop, so how to choose.

Sulfur vulcanization systems commonly used in rubber product formulations include sulfur vulcanization systems, peroxide vulcanization systems, and resin vulcanization systems. Sulfur vulcanization systems are further classified into ordinary sulfur vulcanization systems, semi-effective vulcanization systems, and effective vulcanization systems. Different vulcanization systems have different vulcanization rates. The indexes of the cured EPDM compound are different.

Studies have shown that the use of peroxide-vulcanized EPDM rubber can meet the basic performance requirements of rubber waterstops when vulcanized at 140 °C. Compared with ordinary sulfur vulcanization systems, the vulcanization time is short and can be fixed. To improve the efficiency of production. Therefore, when using EPDM rubber to produce rubber waterstops, peroxide cure systems are a good choice.

When the EPDM rubber waterstop is selected for peroxide vulcanization, the vulcanization process conditions affect the rubber waterstop index, and the appropriate increase of the vulcanization temperature can improve the compression set of the EPDM compound; when vulcanized at 140 ° C, the peroxide is vulcanized. The hardness of the EPDM compound after hot air aging is smaller than that of other vulcanization systems.

Compression set is an important indicator to measure the quality of EPDM rubber waterstop. The peroxide content in the EPDM rubber waterstop formulation also affects the compression set resistance of the compound. Under normal circumstances, when the amount of peroxide is 4-6 parts, the compression set of the rubber can meet the relevant technical standards. When the amount of peroxide in the formulation of the EPDM rubber waterstop is controlled to about 5 parts, it takes about 20 minutes to complete the entire vulcanization process at a temperature of 140 ° C, which is obviously advantageous for production efficiency.

At present, many EPDM rubber waterstop manufacturers use a proper amount of EPDM reclaimed rubber in the rubber waterstop material in order to reduce production costs. The EPDM rubber processed from EPDM unvulcanized rubber or waste EPDM rubber has its own vulcanizing agent, accelerator, activator, etc., which are not completely removed. This part of the compounding agent needs to be taken into account when refining the EPDM rubber waterstop vulcanization system; rationally adjusting the EPDM rubber waterstop formulation containing EPDM reclaimed rubber can reduce the production cost and improve the rubber compound. Vulcanization process performance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits