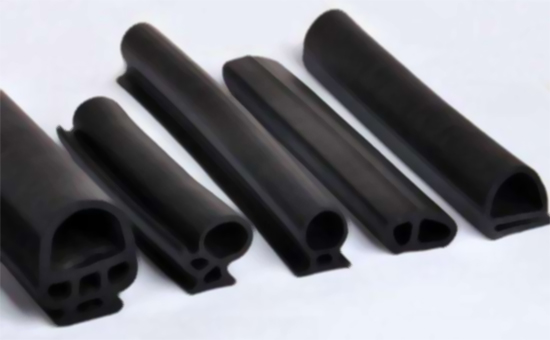

Sealing strips can be found everywhere in daily life, such as automotive seals, mechanical seals, door and window seals, and the like. The raw materials for the production of sealing strips are mostly EPDM rubber. The EPDM reclaimed rubber, which is recycled and reprocessed as waste EPDM rubber, is also favored by the sealing strip manufacturers to replace the EPDM rubber production seal. article. Why is EPDM recycled rubber popular in the production of sealing strips? What are the advantages of sealing strips made with EPDM recycled rubber?

1. Low cost: All reclaimed rubber prices are lower than the corresponding original rubber prices, and EPDM reclaimed rubber is no exception. The price of EPDM reclaimed rubber is about 1/3 of the price of EPDM rubber, and the price fluctuation of EPDM reclaimed rubber is very small compared with the original rubber; therefore, the use of EPDM reclaimed rubber to produce sealing strips is not only Cost can be reduced, and cost stability is high. This is also the main reason why seal manufacturers choose EPDM reclaimed rubber to produce sealing strips.

2, high resistance to high temperature and low performance: EPDM reclaimed rubber is the best in reclaimed rubber products. The high and low temperature resistance of high quality EPDM reclaimed rubber is basically the same as that of EPDM. It can solve the problem that the sealing strip becomes brittle in the cold winter and becomes soft and sticky in the hot summer.

3, good elasticity, good anti-aging performance: EPDM reclaimed rubber has excellent anti-aging performance, can maintain good elasticity during the use of sealing strips, thus prolonging the service life of sealing strip products, such as ensuring doors and windows in door and window sealing strips Air tightness, water tightness, wind pressure resistance and insulation properties.

4, weather resistance, ozone resistance, corrosion resistance: EPDM reclaimed rubber is not only weather resistant, ozone resistant, corrosion resistant, but also has good resistance to ultraviolet light. It can be said that the use of sealing strip products is guaranteed from another angle. life.

When using EPDM reclaimed rubber to produce the sealing strip, it is necessary to select the appropriate reclaimed rubber product according to the specifications of the sealing strip. At the same time, if you want to improve the index of the EPDM reclaimed rubber sealing strip, you can also use the original EPDM. The hardness of the rubber used in the EPDM reclaimed rubber seal has a great influence on the sealing effect. The higher the hardness of the EPDM reclaimed rubber, the better the sealing performance of the sealing strip, and the improvement of the performance without affecting other performances. The hardness of the EPDM reclaimed rubber vulcanizate can extend the service life of the seal.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits