Regenerated rubber aging refers to the rubber compound in the process of storage and use of ozone, oxygen, heat, wind, snow, moisture and the use of mechanical force, the role of chemical solvents, gradually losing value (from the performance and appearance) Phenomenon, manifested as reclaimed rubber molecules destroyed the internal structure, mechanical properties decline. Therefore, the aging resistance of reclaimed rubber has a direct impact on the serviceability and service life of reclaimed rubber products. The most important reason that affects the aging resistance of reclaimed rubber products is that reclaimed rubber types are processed from waste EPDM rubber products EPDM reclaimed rubber is the best anti-aging products.

EPDM is a copolymer of ethylene, propylene and non-conjugated dienes. The diene in EPDM has a special structure. Only one of the two bonds can copolymerize. The unsaturated double bond is mainly used as the cross-linking point. The other unsaturated will not become the main polymer chain, will only become a side chain. EPDM main polymer chain is fully saturated, this feature makes EPDM can resist heat, light, oxygen, especially ozone, so EPDM rubber has excellent anti-aging properties.

EPDM reclaimed rubber raw materials are mostly waste EPDM, waste EPDM rubber products, in the production process retains most of EPDM rubber molecular chain structure, so its anti-aging performance is excellent; The use of EPDM rubber production rubber products even in harsh extreme conditions also have a long service life: such as EPDM renewable rubber products in the ozone concentration 50pphm, 30% elongation under the conditions of more than 150h Ozone cracking occurs.

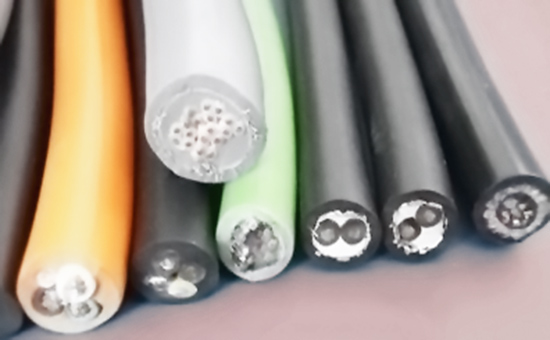

In addition, EPDM reclaimed rubber also has excellent resistance to high and low temperature properties, products can be long-term use at 120 ℃, intermittent use at 150-200 ℃; Polar solution and chemical resistance, low water absorption, Has good insulation properties.

Therefore EPDM rubber with its excellent anti-aging properties and high temperature resistance, corrosion resistance, high insulation properties, widely used in place of EPDM raw materials to produce outdoor wire and cable sheath, EPDM seals, seals Strip, hose, air conditioning pipe, sports facilities sheath, waterproofing membrane, high and low temperature conveyor belt, auto parts and other anti-aging rubber products, significantly reduce the cost of raw materials.

If you use EPDM reclaimed rubber to replace natural rubber to produce rubber products to improve anti-aging properties of products, is not it not suitable? Therefore, rubber products companies in the selection of anti-aging reclaimed rubber products, do not blindly choose the best anti-aging properties of reclaimed rubber, according to their own products use occasions, performance requirements and their own production conditions, choose the most suitable anti-aging regeneration Plastic.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits