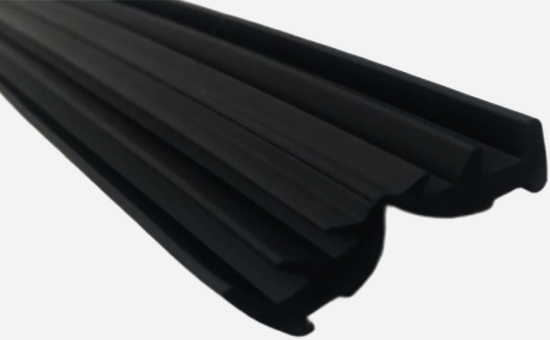

Rubber door and window sealing strip is made of rubber as the main raw material for the sealing material among the door and window frame and glass, window sash, which can effectively isolate dust, rain, noise, etc., EPDM rubber is the main raw material for the production of door and window sealing strip. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, with excellent high and low temperature resistance, ozone resistance, weather resistance, and heat aging resistance, and can be used alone or in combination with EPDM rubber to produce door and window seals to reduce the cost of raw materials.

1. EPDM rubber/reclaimed rubber is used to produce vulcanization formula for door and window seals

(1) 85 parts of EPDM rubber, 15 parts of EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 110 parts of carbon black N550, 58 parts of paraffin oil, 5 parts of black ointment, 3 parts of polyethylene glycol (4000), 6 parts of calcium oxide, 2 parts of accelerator M, 4 parts of accelerator ZDT, 2 parts of sulfur; Total: 296 copies.

(2) 70 parts of EPDM rubber, 30 parts of EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 105 parts of carbon black N550, 25 parts of carbon black N774, 100 parts of naphthenic oil, 10 parts of coumarone resin, 1.5 parts of accelerator M, 1 part of accelerator TMTD, 1.5 parts of sulfur; Total 350 copies.

(3) 60 parts of EPDM rubber, 40 parts of EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 62 parts of carbon black N550, 50 parts of naphthenic oil, 10 parts of antimony trioxide, 20 parts of chlorinated paraffin, 1.5 parts of accelerator M, 0.5 parts of accelerator TMTD, 0.5 parts of accelerator ZDC, 1.5 parts of sulfur; A total of 252 copies.

2. EPDM rubber/reclaimed rubber combined with the production of door and window sealing strip formula design points

When EPDM rubber/EPDM reclaimed rubber is used together to produce door and window seals, a semi-effective vulcanization system or an effective vulcanization system is used, and the vulcanized rubber has better heat resistance and aging resistance, and can be used in combination with peroxides such as DCP if necessary; It is recommended to choose varieties that are not easy to volatilize and not easy to migrate E4LYY1018 for the softening system, and paraffin oil and naphthenic oil are commonly used; Appropriate use of supporting compounding agents, such as ointment, polymer wax, modified plastics, etc., the finished rubber strip has good stiffness and small deformation; Compounding agents such as ointment, mineral oil, clay, stearic acid can also improve the extrusion speed of semi-finished products and keep them smooth.

When EPDM rubber/EPDM reclaimed rubber is used together to produce sponge door and window seals, it is necessary to consider the balance among the pore speed and vulcanization speed generated by the foaming agent and the vulcanizing agent after the use of the foaming agent and the vulcanizing agent according to the process performance requirements, so that the finished rubber strip maintains stable density and uniform pores. The main raw material of Hongyun environmental protection EPDM reclaimed rubber is imported EPDM head glue, which has the characteristics of high glue content, good elasticity, high fineness, environmental protection and tastelessness, which is used for the production of door and window seals, and the surface of the rubber strip is smoother and the aging resistance is better.

EPDM reclaimed rubber has low price, better fluidity and plasticity, easy to mix with raw rubber and compounding agent, dispersed evenly, and the power consumption in the mixing process is much lower than that of the original rubber. In the future, Xiaobian will continue to share with you the application skills of EPDM reclaimed rubber in other rubber sealing strips.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits