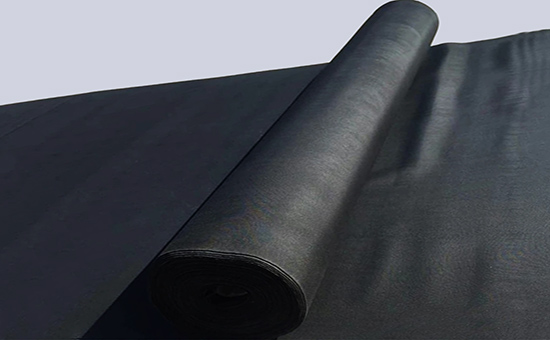

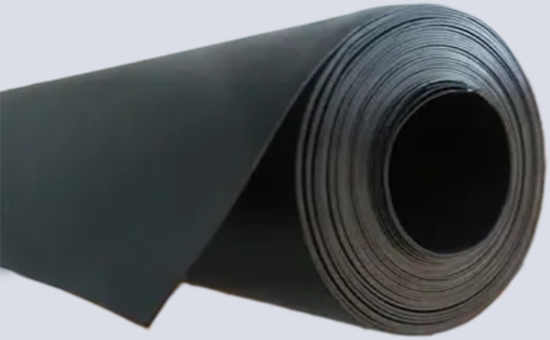

The weather resistance and ozone resistance of the waterproofing membrane produced by EPDM rubber are better than that of neoprene and butyl rubber waterproofing membranes, and are the main varieties of waterproofing membranes in the world. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, excellent aging resistance, and can replace EPDM rubber E4LYY31 produce various EPDM rubber products, effectively reducing the cost of raw materials, and waterproofing membrane is one of them. This article mainly shares the mixing method and vulcanization formula of EPDM reclaimed rubber in waterproofing membranes.

In actual production, EPDM reclaimed rubber can be used alone or in combination with EPDM rubber, butyl rubber, butyl reclaimed rubber, etc. to prepare cost-effective waterproofing membranes.

1. Use EPDM reclaimed rubber alone to produce vulcanization formula for waterproofing membranes

100 parts EPDM reclaimed rubber, 3.5 parts zinc oxide, 0.7 parts stearic acid, 70 parts of carbon black N550, 50 parts of heavy calcium, 30 parts of paraffin oil, 3.5 parts of tackifying resin, 0.6 parts of accelerator BZ, 1.4 parts of accelerator CZ, 0.3 parts of accelerator TMTD, 0.7 parts of sulfur; total: 260.7 parts.

2. EPDM rubber/EPDM reclaimed rubber is used together to produce waterproofing membrane vulcanization formula

75 parts of EPDM rubber, 25 parts of EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 0.5 parts of antioxidant AW, 2 parts of antioxidant MB, 85 parts of carbon black N550, 20 parts of silica, 55 parts of clay, 20 parts of petroleum jelly, 64 parts of paraffin oil, 1 part of coupling agent, 2.4 parts of accelerator BZ, 0.9 parts of accelerator DM, 0.7 parts of accelerator NA-22, 2.5 parts of accelerator TMTD; Total: 360 copies.

3. EPDM reclaimed rubber/butyl rubber is used to produce vulcanization formula for waterproofing membranes

70 parts of EPDM reclaimed rubber, 30 parts of butyl rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 65 parts of carbon black N330, 20 parts of activated calcium carbonate, 20 parts of heavy calcium carbonate, 30 parts of paraffin oil, 5 parts of disproportionated rosin, 1.5 parts of accelerator BZ, 1 part of accelerator CZ, 0.5 parts of accelerator M, 0.5 parts of accelerator TMTD, 1.5 parts of sulfur, 8 parts of calcium oxide; Total: 260 copies.

4. Butyl reclaimed rubber waterproofing membrane mixed with EPDM reclaimed rubber performance improvement formula

85 parts of butyl reclaimed rubber, 15 parts of EPDM reclaimed rubber, 2 parts of zinc oxide, 0.4 parts of stearic acid, 0.3 parts of accelerator M, 1 part of accelerator TMTD, 0.6 parts of accelerator ZDC, 1 part of sulfur; Total: 105.3 copies.

There are three main processing methods for rubber waterproofing membranes: After the rubber material is calendered or extruded, it is vulcanized by indirect steam vulcanization tank (the most used); After calendering or extrusion, the rubber material is vulcanized with hot air; Semi-finished rubber sheets that have been calendered or extruded are used directly to allow them to be naturally vulcanized.

5. Key points of the design of the waterproof membrane matching system for the production of EPDM reclaimed rubber

The use of high wear-resistant carbon black or medium and super wear-resistant carbon black reinforcement can improve the strength of EPDM reclaimed rubber waterproofing membrane and improve the performance of calendering process. Coarse-grained calcium carbonate, or the combination of calcium carbonate and soft clay, can prevent air holes and needle-like bubbles in the waterproofing membrane; Appropriate addition of tackifying resins such as coumaron resin can improve the adhesion of waterproofing membrane rubber.

In addition, if the volatile content of the operating oil used for waterproofing membrane is too high, it will cause the waterproofing membrane to shrink. Therefore, the amount of operating oil should be reduced in the production of EPDM reclaimed rubber waterproofing membrane, and it is recommended to use oil with low volatile content and high aniline point; When using hot air vulcanization, it is recommended to add a small amount of calcium oxide to avoid foaming of the rubber compound.

When using EPDM reclaimed rubber to reduce the production cost of waterproofing membrane, the formula must be reasonably designed, especially the design of vulcanization system, reinforcing system and softening system; In the future, Xiaobian will continue to share with you the advantages and production process points of EPDM reclaimed rubber for the production of waterproofing membranes.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits