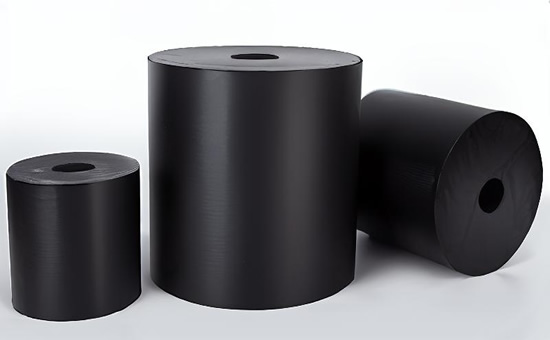

Shock absorbers for mechanical equipment reduce vibration and damage to equipment or structures when they are subjected to external shocks or vibrations. EPDM rubber has excellent heat resistance, ozone resistance, chemical resistance and good electrical insulation, making it an ideal raw material for the production of shock absorbers for machinery and equipment. EPDM reclaimed rubber retains the basic performance characteristics of EPDM original rubber, can it be used in the production of shock absorbers for mechanical equipment? And how to design the vulcanization formula of the shock absorber?

Shock absorbers for mechanical equipment have higher requirements for heat resistance, weather resistance, chemical corrosion resistance, durability, dynamic performance, and shock absorption efficiency of rubber materials. EPDM reclaimed rubber can be used alone or in combination with EPDM original rubber or a small amount of butyl rubber to produce shock absorbers for machinery and equipment, effectively reducing the cost of raw materials. The vulcanization formula of the shock absorber of the machinery and equipment for the production of EPDM reclaimed rubber mainly includes vulcanizing agent, accelerator, vulcanization system, filler, stabilizer, lubricant, plasticizer, etc.

EPDM reclaimed rubber is commonly used with sulfur vulcanization system and peroxide vulcanization system. EPDM vulcanized rubber with peroxide vulcanization has the advantages of good heat resistance, good resilience, small compression set, good electrical insulation, and good color stability of vulcanized rubber. However, peroxide vulcanized rubber has poor tear performance, low tensile strength and relatively poor wear resistance. EPDM reclaimed rubber sulfur vulcanized rubber has good tear resistance, especially thermal tear performance, high tensile strength and good wear resistance; The heat resistance, resilience and electrical insulation of EPDM sulfur vulcanized rubber are relatively poor, the possibility of compression set, metal corrosiveness, rubber frosting is greater, and the color stability of vulcanized rubber is poor.

When designing the vulcanization formula of shock absorbers for machinery and equipment with EPDM reclaimed rubber as the main raw material, it is necessary to select a suitable vulcanization system according to the specific needs of the shock absorber. Appropriate use of reinforcing agents such as silica or carbon black to improve mechanical properties; Use fillers such as calcium carbonate or clay to reduce costs and adjust density. In order to improve the processing performance of EPDM reclaimed rubber shock absorbers for machinery and equipment, it is necessary to add softeners and plasticizers in an appropriate amount, such as naphthenic oil, paraffin oil, polymer plasticizers, etc., to adjust the hardness and flexibility. Choose an antioxidant that can improve the heat resistance, weather resistance, chemical corrosion resistance and wear resistance of EPDM reclaimed rubber vulcanized rubber to prolong the service life of shock absorbers for mechanical equipment.

Examples of vulcanization formulas for EPDM reclaimed rubber to produce shock absorbers: 100 parts EPDM reclaimed rubber, 1.5 parts peroxide, 40 parts reinforcing agent, 30 parts filler, 15 parts plasticizer, 6 parts processing aids, and 1.5 parts antioxidant. The actual formula needs to be adjusted according to the specific product requirements and the characteristics of the reclaimed rubber; Small-scale trials can be conducted to determine the optimal formulation ratio and process conditions.

The vulcanization formula of the shock absorber of the machinery and equipment for the production of EPDM reclaimed rubber is an important link in the production process of EPDM reclaimed rubber, which directly affects the quality of EPDM reclaimed rubber. The reasonable design of the vulcanization formula of the shock absorber of the machinery and equipment for the production of EPDM reclaimed rubber can improve the performance of EPDM reclaimed rubber, reduce the production cost and improve the production efficiency.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits